.jpg)

.jpg)

.png)

.png)

%20(1).jpg)

.png)

.png)

.png)

.jpg)

.png)

.webp)

.png)

.png)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

%20(1).jpg)

.png)

.png)

.png)

.jpg)

.png)

.webp)

.png)

.png)

.jpg)

.jpg)

.jpg)

.png)

Excellent service. Your guys have all been very, very good. You were willing to work around our production needs and come out in the middle of the night to get amongst the rats!

We’ve been staying with these guys because they have the right skills and experience.

Top-rate service. I would recommend your company. I hope we get Paul every time!

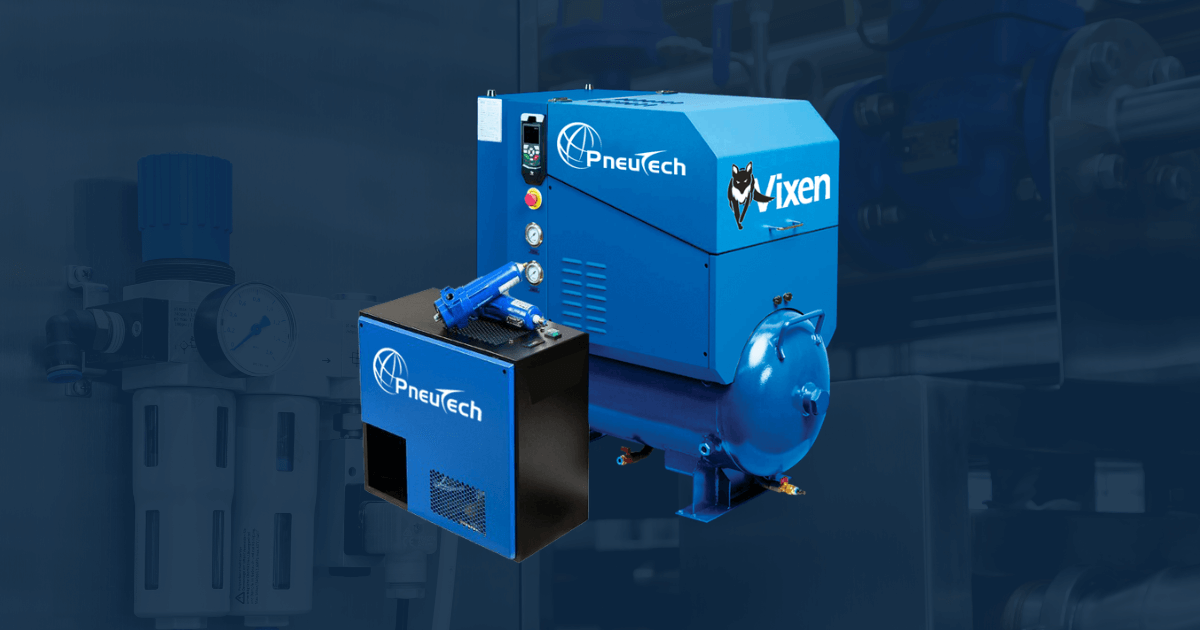

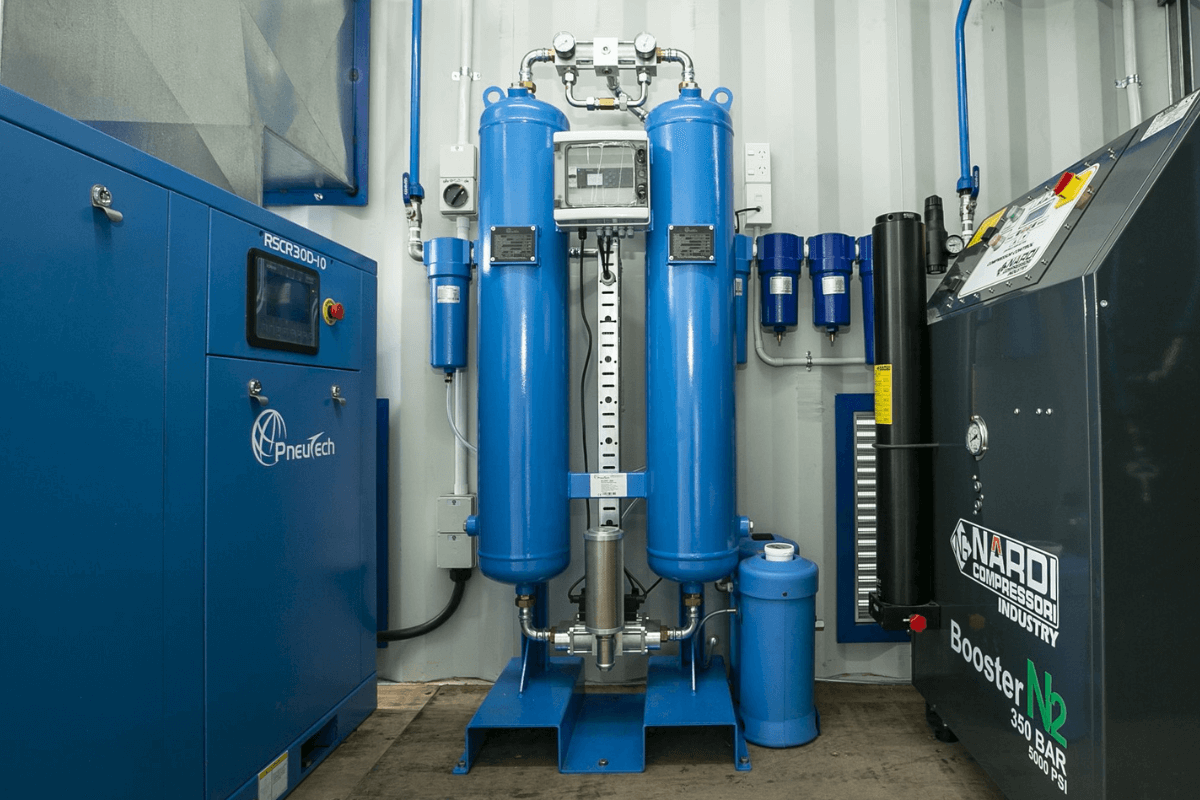

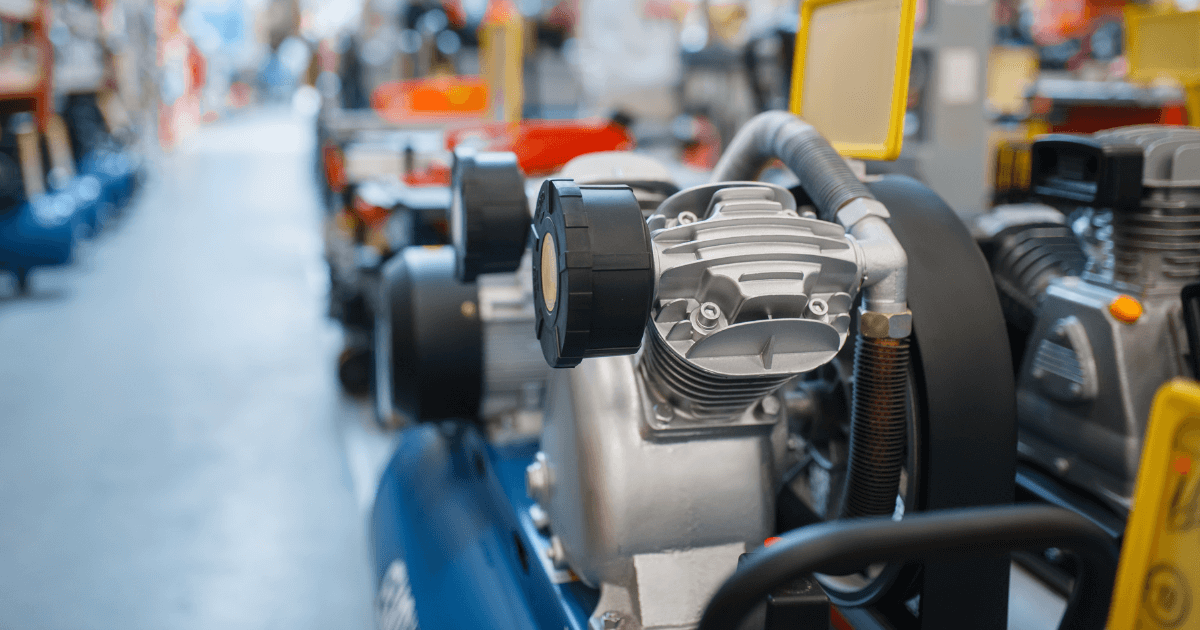

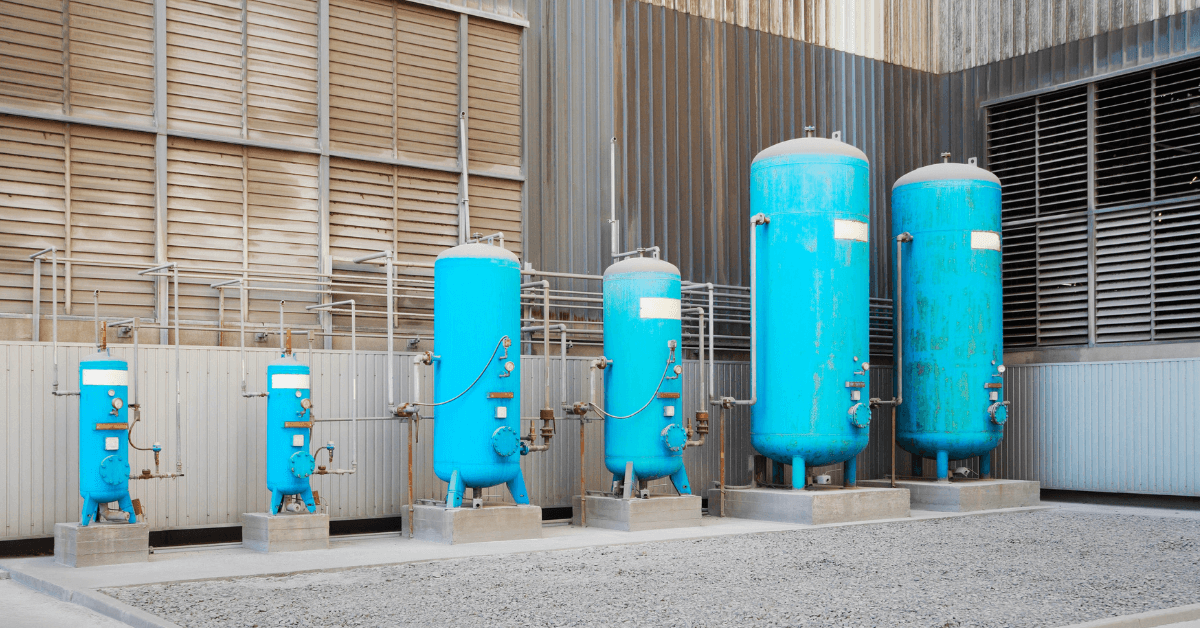

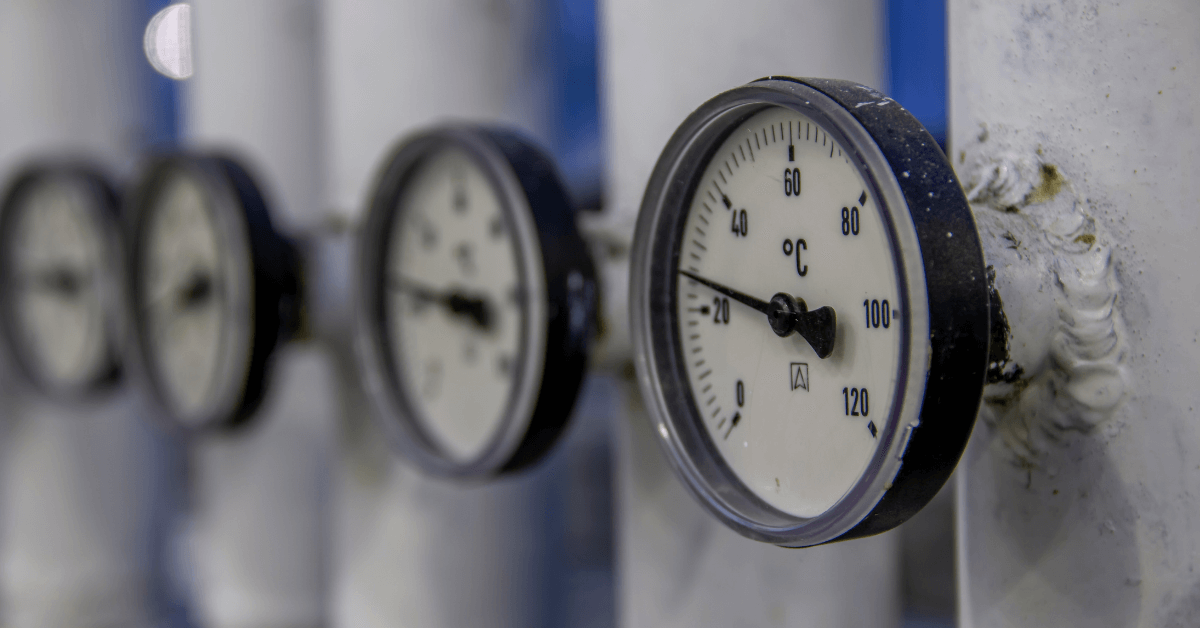

We had an issue with the compressor which these guys fixed. We’re very pleased with Industrial Air Systems. They reacted quickly, kept the unit running while a part was sourced and then fixed it quickly. When we’re looking at any upgrades Industrial Air Systems will be our first port of call.

You ticked all the boxes. Your guys were great. You come in, do the job and leave a pack of biscuits!

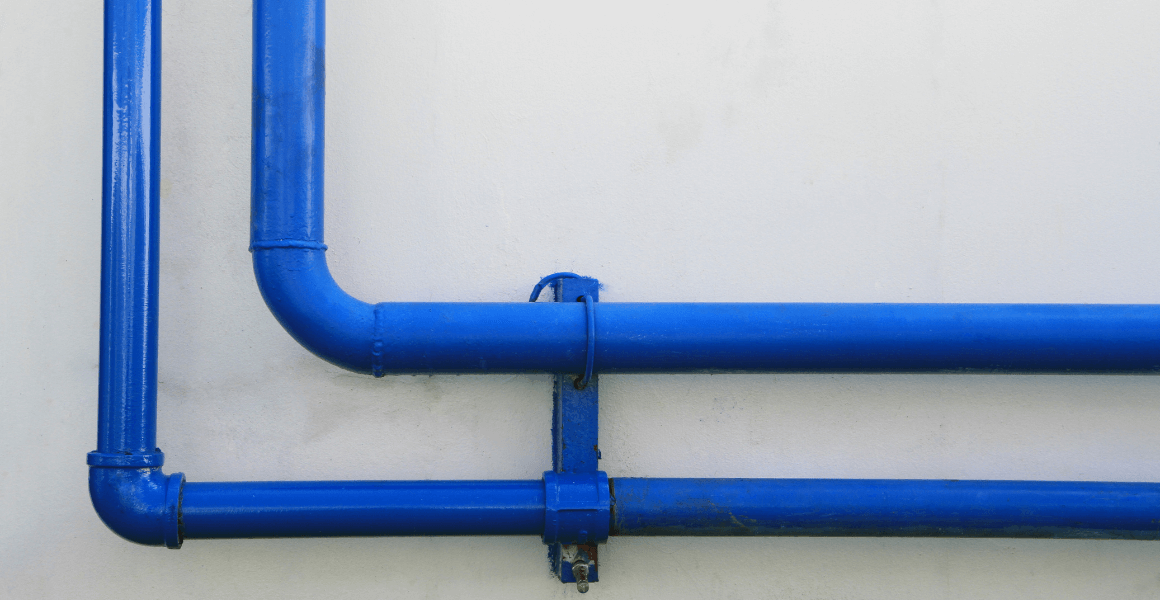

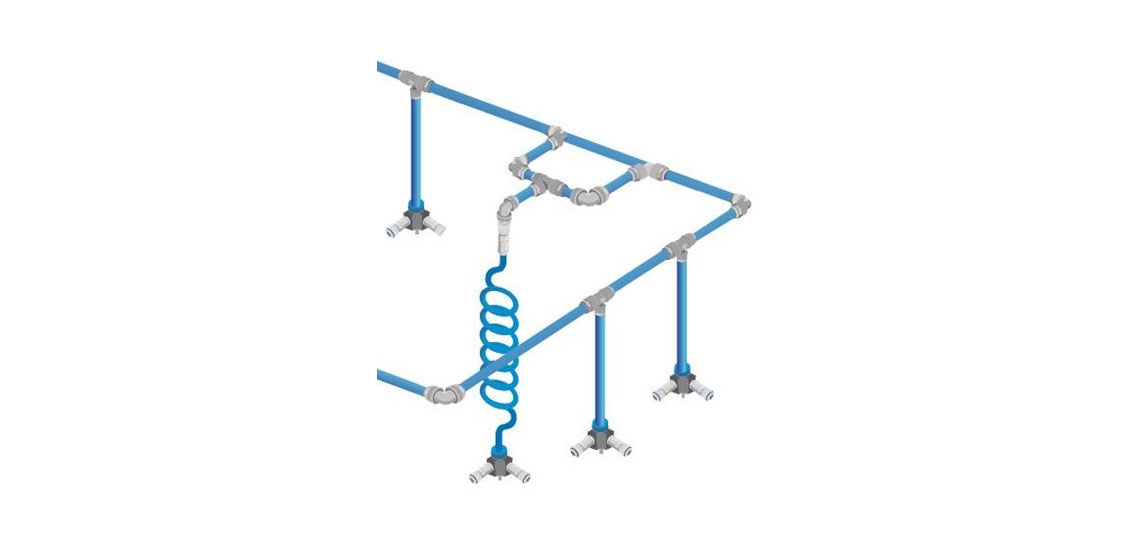

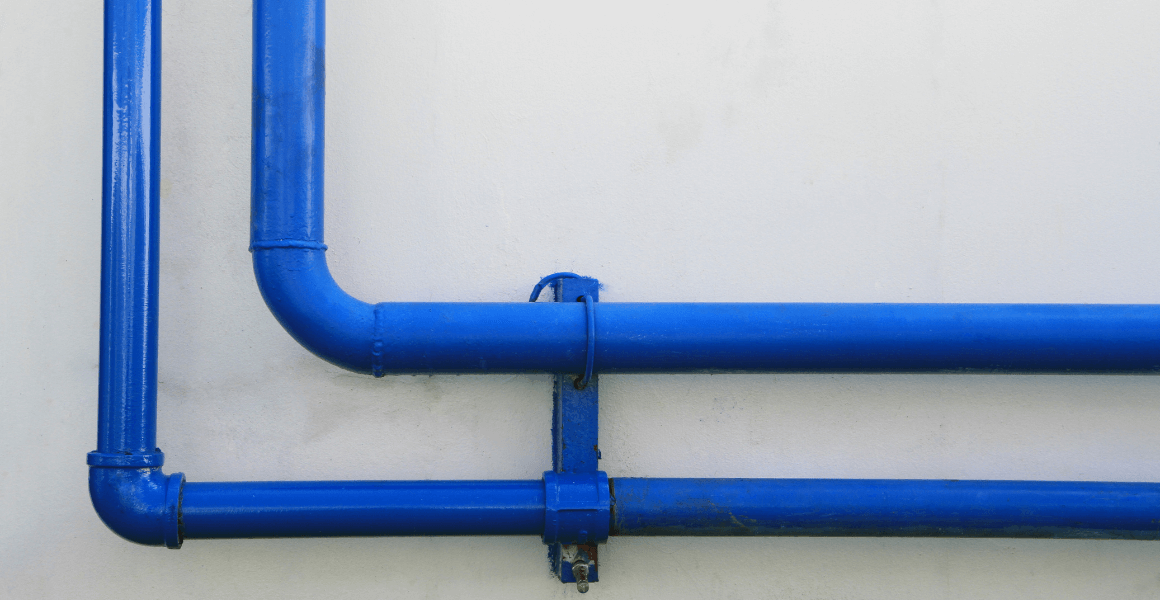

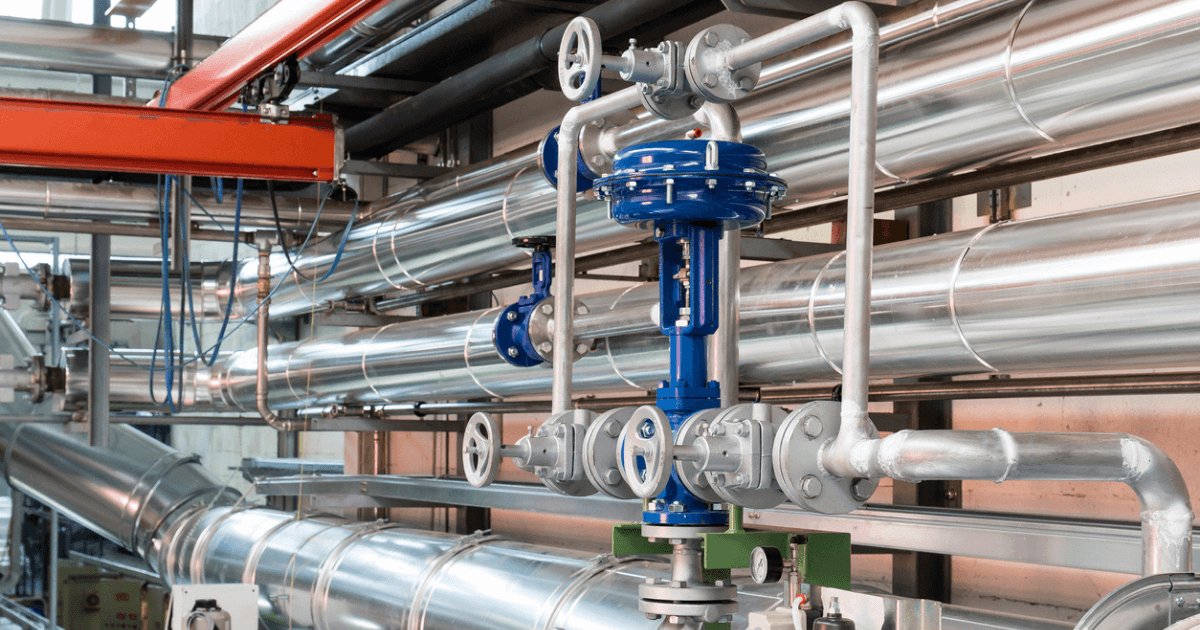

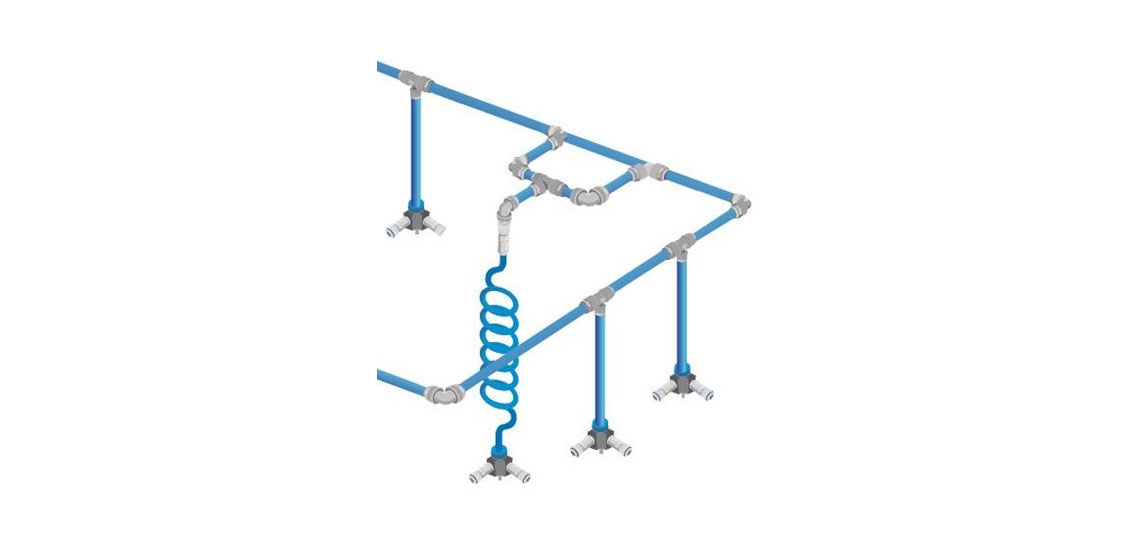

Paul has done a very nice job installing the pipework, it looks awesome. I’m glad that you recommended the aluminium pipe.

We have found Industrial Air Systems very good to deal with and very professional. Good service at a good price. I would not hesitate to recommend Industrial Air Systems to any company considering using them.

[Your tech] is a great guy to work with, he has great knowledge with all the gear and is always there when we need him. All the guys here at VIP love working with him.

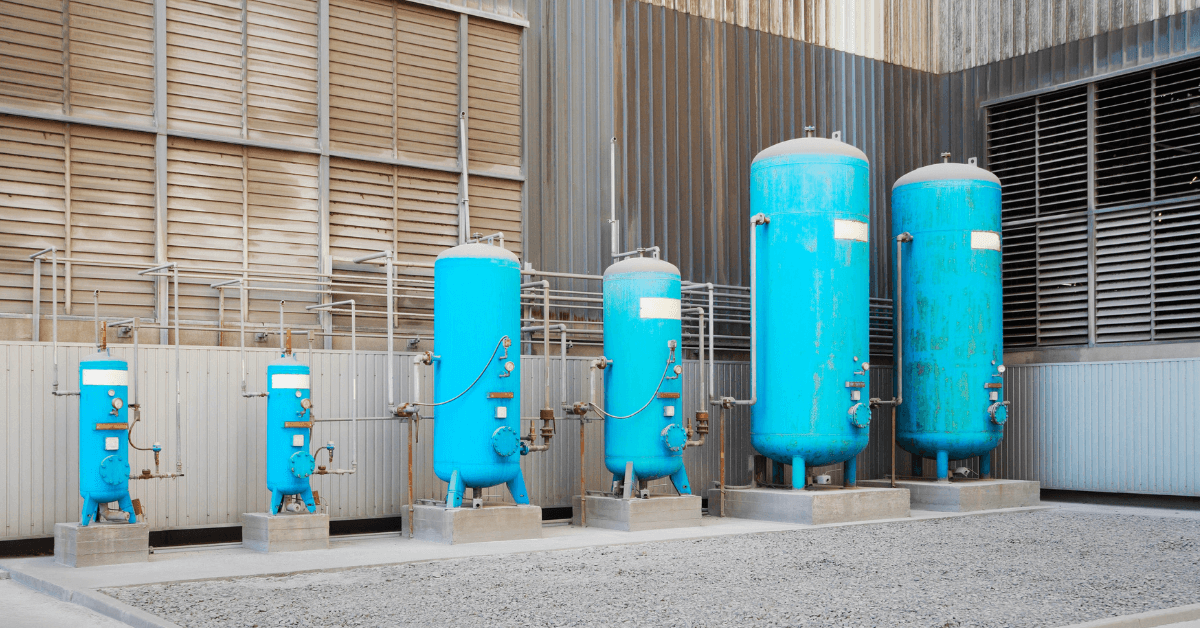

We have had a good experience working with Industrial Air Systems – they are easy to do business with and we have no hesitation recommending them to companies wanting an efficient and economical supply for compressed air.

We have found their service team very responsive and excellent to work with, and from our good experience we would recommend Industrial Air Systems to any company requiring compressed air in the future.

We are very happy with the airlines and the setup. The whole process was easy and we received great communication from you and the team. Your contractor was also great to deal with and did a very tidy job of the install.

Industrial Air Systems NZ © 2025