Are you interested in upgrading your air compressor? Are you looking for ways to improve efficiency and reduce costs? The question is — do you need an oil-free air compressor?

The air compressor you choose influences your product quality, operations, and ongoing costs so we’ve outlined everything you need to know in this article.

What is an oil-free compressor?

Oil-free compressors do not require lubrication because the internal mechanism operates with a minimal amount of friction. Oil-free compressors also use self-lubricating materials and Teflon-coated cylinders instead of oil. This means the compressor air generated is pure ISO Class 1 air or ISO Class 0 air.

While lubricated air compressors may have filtration and dryers to remove impurities, there will always be a contamination risk. Fortunately, with oil-free compressors, the air produced is 100% pure and certified oil-free.

How do oil-free compressors work?

There are various types of oil-free compressors, including rotary screw air compressors, piston compressors, and scroll compressors. It is important to note that some of these compressor types will be lubricated but it is possible to get oil-free versions. We’ve outlined how each type of compressor works below.

Oil-free rotary screw air compressors

- Air enters the compressor chamber and two screw rotors rotate at high speeds.

- This traps air between the rotors and moves it down the chamber.

- The chamber decreases in size, increasing the pressure and condensing the air.

- The discharge valve opens and the air enters a receiver tank.

- Air is transferred downstream for drying and contamination removal.

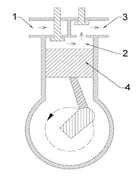

Oil-free piston compressors

- The piston moves away from the cylinder head, creating a vacuum above it.

- The intake valve opens, allowing air to fill the area above the piston.

- The piston ascends, compressing the air in a single stroke.

- Once the air is compressed, the piston releases it through the discharge valves.

Oil-free scroll compressors

- The orbital element moves inside the static element. The scrolls are interlocked but not touching, meaning they do not need lubrication.

- The crescent-shaped chambers of air between the scrolls get progressively smaller.

- The air moves towards the centre of the scroll housing, compressing as it goes. A

- The air eventually passes through an outlet port, ready to be dried, stored, and used.

Benefits of oil-free compressors

Certified oil-free air

In certain industries, strict cleanliness standards must be met to ensure quality production. In these applications, oil-free air compressors are crucial because they guarantee 100% pure air that meets Class-0 air quality standards for ISO Class 1 air or ISO Class 0 air.

For this reason, the following industries and end uses must use oil-free air compressors:

- Pharmaceutical

- Food and beverage

- Electronics

- Textiles

- Robotics

- Automotive

- Painting

- Aerospace

- Plumbing

For the highest air purity level, our RSCRD-V air compressors meet Class-0 Certification so there’s no need to worry about air/oil separator changes or oil contamination testing. These compressors eliminate all traces of oil contamination directly at the source.

Discover our oil-free RSCRD-V air compressors »

Sustainable

An oil-free compressor is the most sustainable solution because it minimises oil consumption and doesn’t release any pollutants. Compared to an oiled compressor, which consumes approximately 55 gallons of oil every six to twelve months, an oil-free model only needs an oil change every two or three years.

Oil-free compressors also eliminate the need to dispose of air compressor oil or other harmful substances, reducing the risk of exposure for your workers. Condensate from oil-free compressors can simply be discarded or recycled within your plant.

Improved start-up speed

While oil-based compressors are dependent on the viscosity of oil, an oil-free compressor is more consistent and reliable. This means you can continue operations as needed, with fast and predictable start times.

Low maintenance

The only regular maintenance we recommend for an oil-free compressor is draining the tank after each use. Since there’s no sliding or rubbing of internal parts, they sustain much less wear and tear, resulting in fewer repairs over the compressor’s lifetime. They also reduce the frequency of oil changes and eliminate the need to dispose of old oil aerosols.

Additionally, oil-free compressors do not leave any oil build-up in your end-use pneumatic equipment, reducing repairs and replacements.

Low cost

Generally, oil-free compressors are the most affordable option to purchase, operate, and maintain. The running costs are far lower than oiled alternatives, with less time and money spent on repairs and replacements. With some models, you can even regulate energy use in operational downtime to reduce your annual fuel usage.

Oil vs oil-free air compressor

Oiled air compressors use oil to keep internal parts moving properly, which is effective for applications where air purity is not critical. For end-use applications where air must be pure, such as food and beverage, an oil-free air compressor is more suitable. For more information, read our article answering the question, do I need an oil-free air compressor?

Best oil-free air compressor NZ

PneuTech's RSCRD-V series — 100% oil-free

The PneuTech RSCRD-V Series of oil-free compressors is renowned for its superior performance and high level of air purity. Combining a superior 2-stage air end and a high-efficiency motor, our RSCRD-V compressors ensure safety and reliable performance for any facility. Key features include:

- 100% oil-free Class-0 Certification

- Variable Speed Drive (VSD)

- Teflon-coated rotors

- Sterile stainless steel

- Standby function

- Intelligent microcontroller

- Two-stage air ends

- Air or water-cooled

.jpg)