Servicing your air compressors is critical to improving your productivity. By maintaining your air compressor equipment regularly, you will significantly reduce downtime, damage, and repairs.

In this article, we advise how often your air compressor should be maintained, including key timings of various services.

Air compressor repair services

Each compressor and system has slightly different maintenance needs so we always recommend speaking with your supplier to gain tailored advice. However, we have outlined the key maintenance tasks you should be aware of.

Clean and inspect your compressor

We suggest conducting a base-level clean and inspection every month. This ensures any surface dirt and build-up are dealt with sooner and allows you to pick up on any problems before they escalate.

Check the condensate oil and water separator

For oiled feed air compressors, you will need to check the oil/water separator every 1,000 to 2,000 hours of use. This check should include basic cleaning, and checking the drainage, water level, and oil build-up. In addition, after every 2-4,000 hours of use, you should also check the condensate drains and change the absorption material.

Replace the filters

You should replace your air compressor filters between 1,000 to 2,000 hours of use. This includes the air, oil, and panel filters (if applicable).

Replace the lubricant

Regardless of usage hours, lubricant oil degrades over time and needs to be replaced. This can cause severe air end failure, requiring expensive repairs and potential damage to your workpiece. It is far more cost-effective to change the oil once a year or more. High-quality oil also guarantees optimum compressor performance and increases the longevity of your air needs.

Check condensate drains

At least once a month, we recommend checking that your condensate drains are functioning properly. This ensures the moisture is not building up inside your machine and causing problems internally. This simple routine dramatically reduces the risk of machine failure and damage.

Check valves

We suggest checking the drain valves and/or switching valves every month. This ensures they are functioning correctly and allowing air to flow as needed.

Check belt tension

If you have a belt-driven rotary screw compressor, the belt will loosen over time and impact operational efficiency. To avoid this, you need to check and adjust the tension of the belt every month.

Check the desiccant air dryer

For compressors with a desiccant air dryer, you should conduct a basic check every 3 to 6 months. This check should include thorough inspections of the monitor dew point, switching valves, muffler, and desiccant. In addition, every 2 years you should conduct a full check that also inspects the related pre and post-line filtration elements.

Check the refrigerated air dryer

For compressors with a refrigerated air dryer, you should conduct a basic check every 1,000 to 2,000 hours of use. This includes a check of the test drain valves, clean strainers, blow-out condenser coils, and suction pressure. Every 4,000 hours of use, you should check the airline filtration elements as well.

Need maintenance or repair? Submit a service enquiry with us today >>

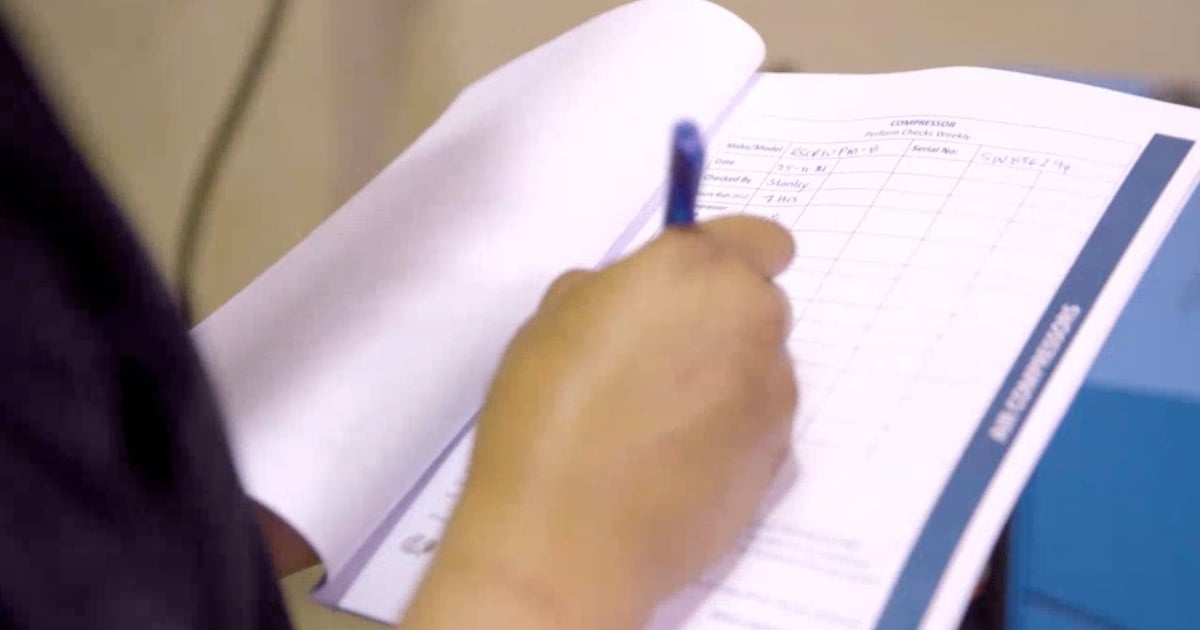

Air compressor maintenance schedule

Daily

At the end of every operational day, drain all condensate from the air receiver tank.

Weekly

At least once a week, drain all condensate from the compressor air or oil tank and check the oil level. If the oil level is below the minimum line, top it up.

Monthly

At least once a month, clean the air inlet filter. The time per filter will depend on how much your compressor is being used so speak to us for our tailored advice based on your operations.

6 months

Every six months, check the oil levels, airline connections, and belt tension. Keep an eye out for any air leaks and tighten the connections accordingly.

Annual

Every year, you need to change the oil, the oil filter, and the air inlet filter. You should also clean any dirt from the fins and surface of the air/oil cooler.

Two years

At least once every two years, you will need to change the air/oil separator filter.

We've made air compressor maintenance easy with a free checklist. Get yours here >>

Air compressor repairs nz

If you need engineering and compressor services, Industrial Air Systems is here to help. We understand the importance of productivity so we offer guaranteed service backup 24/7, 365 days a year. We offer engineering compressor services for all of our products, ensuring your team stays operational at the most crucial of times.

When you partner with us, you are backed by our Master Maintenance team. That means you’ll receive quick, professional, and effective servicing when you need it.

Our 5-point service pledge:

- We arrive on your site as promised.

- Your machine will look better than when we arrived.

- The majority of issues will be addressed during our first visit to the site.

- Our knowledgeable technicians can inspect any brand and any type of compressor.

- We advise the best-care approach to maintain your equipment.

Click below to find out more about our maintenance services or submit a service enquiry.

.jpg)