There are several types of air compressors available, and each has particular characteristics that suit certain applications. The most commonly used designs are rotary screw compressors, piston compressors, and scroll compressors.

When choosing an air compressor, there are a few key factors to consider. A scroll compressor ticks all the boxes with its convenient size, efficient flow and high-quality air. To help you decide if this is the best type of compressor for your application, this blog contains everything you need to know about scroll compressors, along with the specific benefits of the PneuTech RSCRXA range.

Scroll compressors explained

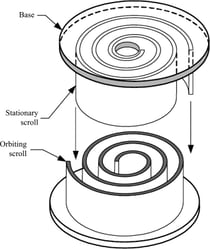

Scroll compressors, also called spiral compressors or scroll pumps, are a type of positive displacement compressor. Inside the outer shell are two identical spiral-shaped scroll elements which are coupled together. One of the elements is fixed while the other orbits inside it, powered by a motor.

Scroll compressor diagram (source).

How does a scroll compressor work?

To understand the mechanics of scroll compressors you first need to know what positive displacement is. Positive displacement compressors work by introducing an amount of air into a cylinder with a moving component like a piston or plunger. This mechanism then reduces the volume of the cylinder and forces the air to condense in the remaining space. This is also called internal compression.

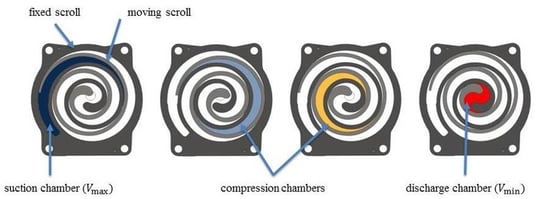

In the case of scroll compressors, the orbital element moves inside the static element and the crescent-shaped chambers of air between them get progressively smaller. The air moves towards the centre of the scroll housing, gradually compressing as it goes, and eventually passes through an outlet port. A non-return valve prevents any backflow, and at this point, the compressed air is ready to be dried, stored and used.

Compression principle of a scroll compressor (source).

Scroll compressor applications

Oil-free scroll compressors are suitable for a broad range of industries including research labs, hospitals, food and beverage, electronics, textiles, pharmaceuticals, universities and dental.

That’s largely due to the fact the air produced is clean, pure and oil-free. In many cases, compressed air quality is critical because it can cause damage to the products made with it. For certain situations where businesses must adhere to strict guidelines and regulations, this cannot be risked. Even if the chance of contamination is small, these businesses generally opt for oil-free compressors because it minimises the need for product recall or expensive overhauls.

Benefits of scroll compressors

Scroll compressors have been around for a long time and have proven to be incredibly effective. So if you are considering a scroll compressor, here are some key benefits to consider.

Energy efficiency

Scroll compressors are the most efficient type of compressor available because the design is simple and the operation can be switched on and off as required. The scroll design has fewer moving parts and less torque variation than a reciprocating compressor, meaning the movement is far smoother.

Compact footprint

For many industries, an air compressor needs to be small and inconspicuous. Scroll compressors are the perfect solution because the inner workings of the compressor are encased in a tidy protective shell. The shell is box-shaped and discreet, allowing work operations to continue safely and without unwanted disruptions.

Low noise level

Due to the arrangement of the scroll compressor, there is a larger compression chamber which means it doesn’t need to be operated at such high speeds. This means they don’t produce as much noise as other designs and can be used without the need for any ear protection. The noise also won’t interrupt a normal conversation, making it perfect for many applications.

Reliable and low maintenance

The inner workings of scroll compressors are much simpler than other types, meaning they are more reliable and generally require less upkeep. As well as that, the revolutions per minute (RPM) are far lower, ensuring a long operating lifetime. As long as regular servicing is kept up and the scroll compressor is cared for, it shouldn’t need any major maintenance for a long time.

Certified oil-free air

One of the most important benefits of scroll compressors is that they are oil-free. For other air systems, inline filters can help to avoid oil mist and contaminants, but they can’t always be guaranteed to work. Scroll compressors, however, eliminate this risk and ensure the purest air, safe for all industries. By providing certified oil-free air, you can prevent your products from being spoilt and avoid expensive legal claims.

The Industrial Air Systems range of scroll compressors

At Industrial Air Systems, we have a range of air compressors available, including the PneuTech RSCRXA scroll compressor. For applications that require pure air, this model is a perfect choice because it’s oil-free and produces Class 8573.1 air. It also runs quietly and includes fewer serviceable internal parts meaning no oil or filter changes.

In the RSCRXA series, each compressor model has its own high-quality and world-renowned Anest Iwata airend. These airends, or screw elements, are the heart of the compressor and the part that determines the quality and efficiency of the overall machine. Airends allow the modules to be controlled on demand and since there is no offload cycle, it will stop as soon as they reach the set pressure, saving users from unnecessary running costs.

We also have a range of rotary screw air compressors that will suit many other industrial applications. If a scroll compressor isn’t the ideal solution for you, the PneuTech RSCRV and RSCRPM series’ of variable-speed rotary compressors are worth considering. All of the compressors that we stock are well-regarded for their exceptional performance and superior air quality. These machines are built with innovative technology and time-tested engineering processes that ensure the efficiency and accuracy required in many industries. In fact, by tailoring the airflow according to the consumption, they can save as much as 60 percent power.

If you’re not sure which type of compressor is the best fit for your needs, talk to the team at Industrial Air Systems. We’ve worked with businesses from a variety of sectors and have the know-how to help you make an informed decision.

To learn more about our scroll compressors, our downloadable brochure has everything you need.

.jpg)