When the team at Orams Marine needed a compressed air system for their 30-metre high facility, they wanted efficiency and functionality. The extremely high roof posed a unique challenge, but the team at Industrial Air Systems were keen to take on the task.

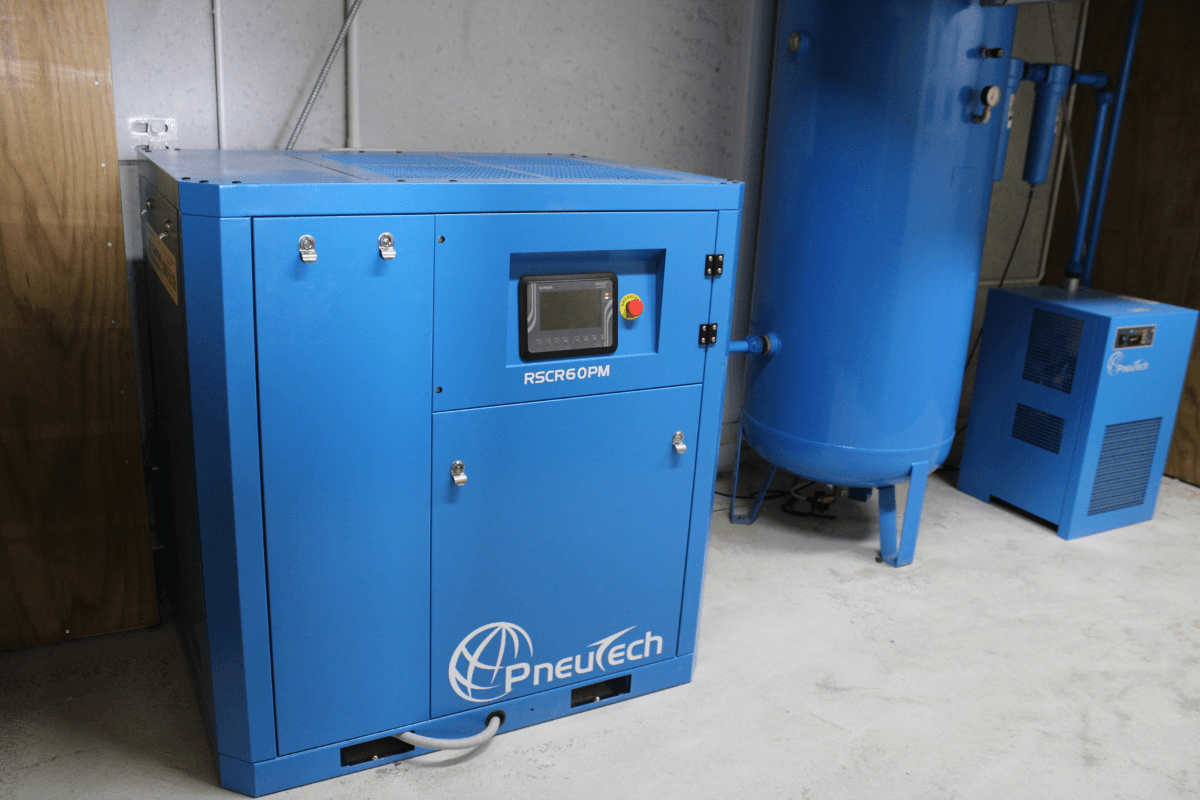

The new RSCR60PM Plus variable-speed compressor system supplies consistent air to the knuckle boom at various heights, suitable for boats of all shapes and sizes. The pipework connects to the dry docks from a central machine, keeping installation costs low and fixed.

PneuTech RSCR60PM variable-speed, permanent magnet compressor setup for Orams Marine.

PneuTech RSCR60PM variable-speed, permanent magnet compressor setup for Orams Marine.

.jpg)