Boating has always been a popular pastime for many of us here in New Zealand – a chance to get out and explore more of our own backyard while catching a fish or two while we’re at it! Warmer weather across the country and more Kiwis staying local due to restrictions on overseas travel has seen demand for boats soar. Trade Me reported a 14 percent increase in the number of boats sold purely by auction in December, compared to those sold in the same time of 2019.

With more people investing in boats across the country, there’s also growing demand for specialist services and skilled teams that will take care of and maintain these impressive vessels. Gloss Boats Marine Spraying is just one of the specialist companies available that provide repair and maintenance services for boats.

The team at Gloss Boats are currently working on a new facility, due to open in March of this year. We were privileged to be approached by Gloss Boats to carry out and supply the compressed air needs required for this new facility. Read on to learn more about this project, and the compressed air system we are supplying.

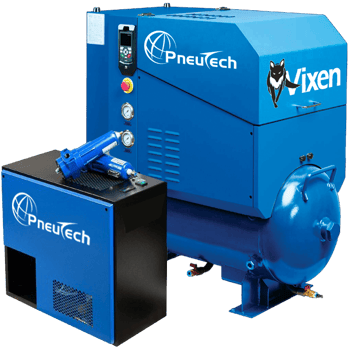

Air compressor and dryer supplied for Gloss Boats.

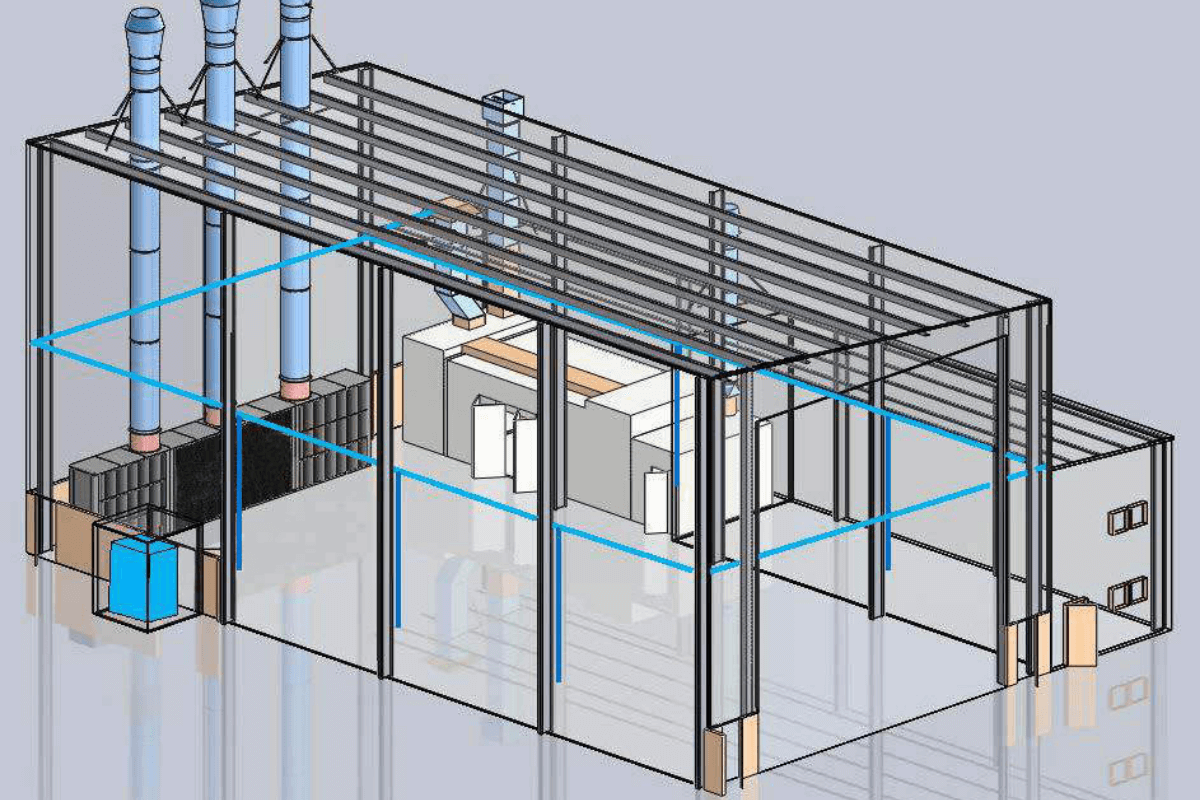

Air compressor and dryer supplied for Gloss Boats. Progress shots of the new shed being built.

Progress shots of the new shed being built.

.jpg)