Are you looking for a reliable and high-quality nitrogen generator for your business? It may be worth investing in an on-site PSA nitrogen generator.

In this article, we explain what PSA nitrogen generators are, how they work, and how to decide if this is the right choice for your business. We also showcase our range of nitrogen generators, designed to supply high-quality and reliable gas supply for your plant or factory.

Nitrogen generation

Nitrogen generators are commonly used in a range of industries, including food and beverage, dairy, wine, pharmaceutical and medical, and beer brewing. Drawing from the atmosphere, a nitrogen generator separates nitrogen from other molecules to be used in its pure form.

Since nitrogen is the most abundant gas in the earth’s atmosphere, it is a more reliable gas supply than most alternatives. With an on-site nitrogen generator, you can produce high-quality and consistent nitrogen on demand, reducing plant downtime significantly.

The two types of nitrogen generators include:

- Membrane nitrogen generators

- PSA nitrogen generators

What is a PSA nitrogen generator?

A PSA nitrogen generator uses Pressure Swing Adsorption (PSA) to separate various gas components from the air. The generator fixes these gas components and particles with a solid substance, called an adsorbent. Common examples of adsorbents include zeolite, activated carbon, silica gel, alumina, or synthetic resins.

How does a PSA nitrogen generator work?

In a Pressure Swing Adsorption generator, the oxygen, carbon dioxide, and water vapour are stuck to a carbon molecular sieve, while the nitrogen flows through. A PSA nitrogen generator contains two separate pressure vessels – Tower A and Tower B. Each is filled with a carbon molecular sieve that switches between separation and regeneration. The process is as follows:

- The separation phase begins when clean, dry compressed air enters tower A.

- Oxygen molecules pass through the tower A sieve but nitrogen molecules cannot fit so they bypass the sieve.

- Some nitrogen from tower A flows into tower B in the opposite direction, triggering the regeneration phase. The rest is ready for use.

- The opposite flow of nitrogen pushes oxygen from a previous separation phase out of the sieves in tower B.

- When the oxygen has been removed, a new cycle of compressed air is introduced for separation.

- The cycle repeats, alternating between separation and regeneration in each tower.

Pros and cons of PSA nitrogen generators

PSA generators are popular across a range of industries, depending on the application. Generally, PSA generators are used for their high-quality nitrogen, long lifespan, and flexibility. We’ve outlined the pros and cons below.

Advantages of PSA nitrogen generators

Quality of nitrogen gas

PSA nitrogen generators can provide up to 99.9995% pure nitrogen. If you need a high level of purity for your end use, this is well worth the investment.

Reliability of nitrogen generator

PSA nitrogen generators can operate 24/7, giving you an uninterrupted flow and productivity.

Flexibility

Provided the PSA nitrogen generator meets the flow and purity requirements of the application, the settings and end use can be adjusted with minimal hassle.

Onsite nitrogen supply

On-site nitrogen production eliminates the need for cylinder deliveries and third-party dependency. This also provides significant savings, with lower net costs and no delivery fees.

Long lifespan

PSA nitrogen generators are highly resistant to vibration and shocks, chemically inert to greases and moisture insensitive. Provided you take proper care of your generator, it can easily last more than a decade.

Disadvantages of PSA nitrogen generators

Capital investment

A PSA nitrogen gas generator is a significant initial upfront investment and costs more than a membrane nitrogen generator. However, depending on the end-use, the high level of air purity may be worthwhile and you will generally be able to recoup the expense within 12 months by saving on cylinder deliveries.

PSA Nitrogen Generators NZ

Do you need a high-quality and reliable nitrogen gas supply for your business? Here at Industrial Air Systems, we supply a superior range of nitrogen generators by PneuTech.

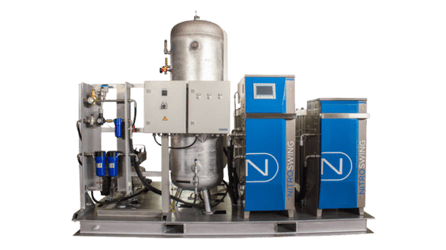

Skid-mount nitrogen generator

From 2.6m3 at 99.999% purity. Assembled and fully commissioned at our factory. Mounted on a strong steel base, this nitrogen generator package is delivered, and ready to go.

Containerised nitrogen generator

From 2.6m3 at 99.999% purity. Assembled and pre-commissioned at our factory. This nitrogen generation package comes complete in its very own shipping container.

Factory-install nitrogen generator

2.6m3 at 99.999% purity. Assembled and commissioned in your factory, this nitrogen generator package is custom-designed to suit your existing plant and requirements.

Nitrobrew nitrogen generator

Pure nitrogen gas for breweries. An all-in-one nitrogen generator unit perfect for all beer brewing needs. Delivered to your brewery, ready to go.

Nitrovin nitrogen generator

Pure nitrogen gas for wineries. An all-in-one nitrogen generator package for use in wine making. Delivered to your winery, ready-to-use.

For more detailed specifications and recommendations, download our full Nitrogen Generators Brochure.

.jpg)