If you’re looking for a new laser cutter, the ongoing costs should be a major part of your decision. When it comes to efficiency, productivity, and cut quality, you need to be confident that your laser cutter is the most effective machine for the job.

In this article, we explore the key factors that affect the running costs of a laser cutter, so you can decide which machine is best suited to your operations. Read on to find out how the right laser cutter can help to improve your bottom line.

The process of laser cutting

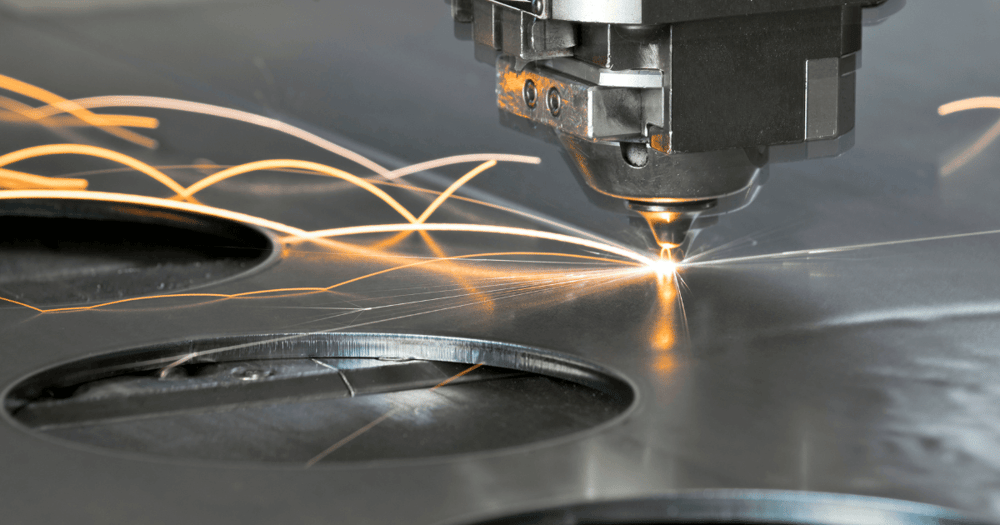

In laser cutting, a powerful laser beam is directed towards the item that needs to be cut. The intense heat melts the material along its path and an assist gas is blown on the molten material to enhance the quality of the cut edge.

The laser cutter is controlled by computer-aided design (CAD) software to create the desired shape. This adapts the cutting speed and laser power based on the material type and thickness to ensure precise and accurate outcomes.

A laser cutter uses a powerful laser beam and the intense heat melts the material along its path.

Laser cutter cost factors

When using a laser cutter, the running costs depend on a wide range of factors, including:

- Power

- Maintenance

- Material thickness

Power

One of the most significant ongoing costs for a laser cutter is the energy used to power it. This will depend on the type of laser cutter you have and the average time you spend using it.

1. Actual working time

Firstly, you need to calculate how much time it takes the laser to perform a given engraving or cutting task. This is especially helpful if you execute the same task repeatedly as you can use it to calculate the average power usage over time.

2. Efficiency

A more efficient laser cutter will require less power to produce the same results, meaning less power is wasted as heat or other forms of energy. Additionally, a more efficient laser cutter can often operate at a lower power level while achieving the same cutting results, consuming less power overall. This results in reduced power consumption overall and lower running costs.

Maintenance

You will also need to account for any servicing costs that may arise while using and maintaining a laser cutter. Routine maintenance will keep your laser cutter running efficiently and effectively, reducing the likelihood of breakdowns, repairs, and replacement parts. This helps to improve efficiency and reduce downtime, saving you more money over time.

1. Regular servicing

When done regularly, servicing can help to ensure the laser cutter is running efficiently. This can help to lower the energy bills associated with running the laser cutter. In most cases, we recommend the following for servicing:

- Every 6 months: Change the pre-filter which is wrapped around the HEPA element.

- Every 12 months: Change the HEPA filter itself.

It is also common practice to monitor and clean the mirror and lens, exhaust fan area, tube filter and water cooler on a regular basis or as needed.

2. Repairs

If your laser cutter breaks or needs fixing, you may need to invest in costly repairs or replacement parts. If you arrange regular servicing, these events should be less frequent.

3. Travel costs

If the repair person has to travel far to get to your equipment, you will need to account for higher travel costs. They are likely to charge for travel time, especially if the callout is unplanned or your site is far away from their main service routes.

4. Downtime

If a laser cutter breaks down or is being serviced, downtime can result in lower productivity and lost revenue. If you plan your servicing in advance, you can help to reduce the likelihood of unforeseen breakdowns.

Material thickness

The material you are cutting has a direct effect on the overall laser-cutting costs of your project. Generally, the thicker the material, the more time it takes the laser to penetrate and cut through it. For thinner materials, such as sheet metal, you may also be able to layer them and process multiple pieces simultaneously. This increases your output with minimal increases in effort, reducing costs.

Speak to our experts to find out which laser-cutting technologies are appropriate for your materials. We can find a solution for any material, including aluminium, copper, mild steel, carbon steel, stainless steel, and brass.

Energy-efficient laser cutters

You can reduce operational costs significantly by selecting the right laser-cutting system for your needs. Not only will your machine be better suited to your output, but maintenance will also be reduced.

At Industrial Air Systems, our team can help you find the most efficient laser-cutting solutions for your operations. We’ll tailor the solution to suit your particular needs, factoring in the materials you need to cut and the average time spent on each task. To help you get started, we’ve outlined two of our most cost-effective laser cutting systems below – the Airpak15 and the Nitropak.

Airpak15 Air-Assist Air Compressor

The PneuTech Airpak15 provides contaminant-free air, specifically designed to supply laser cutters. The absorption dryer can reduce compressed air to a dewpoint of below -40ºC and the carbon tower eliminates residual oil vapours, ensuring no contamination enters the laser supply line.

Learn more about this laser cutting system >

Nitropak Laser Cutting Generator

The Nitropak is a complete nitrogen generator system, designed to perform all laser cutting operations from one compact, containerised package. By using an inert gas, the system provides contaminant-free air, allowing for high-quality cuts. The Nitropak features a 7-stage low and high-pressure filtration system to separate any oil contamination down to 0.01 microns.

Learn more about this laser cutting system >

As industry experts, we stay informed of the latest laser cutting technologies and are always happy to assist you. Reach out today or explore our laser cutting products for the right compressed air system for your workshop.

.jpg)