Need to contact us?

The friendly Industrial Air Systems team are here to help! Contact us now with your compressed air request and we'll be back in touch by phone or email, as soon as possible.

The air produced by compressors usually contains water, dirt and other unwanted particles that can contaminate your plant and equipment. This results in increased and costly downtimes, and vital production quality reductions. Dry compressed air ensures that the air your compressor produces is clean and free of contaminants.

Adding a refrigerated dryer to your compressed air system, along with the appropriate filtration will deliver 99% moisture-free compressed air. And with the addition of a desiccant dryer, you will achieve clean and dry compressed air down to a -40C pressure dewpoint.

View our air treatment products below, or enquire with us today to discuss your needs.

-70°C - 3°C dewpoint range. Refrigerated and desiccant dryers including heated, blow-purge, heat-of-compression, modular and combination dryers for all applications.

16 bar - 420 bar pressure. Process low, medium, and high pressure and desiccant filtration. Condensate separators, filtration gauges and drains are also available.

Remove oil residue. Safely remove oil residue from compressed air condensate to keep waterways contaminant-free. All compressed air applications and sizes are covered.

6 to 6,500 Nm3/hr flow rate. For separating oil vapours from compressed air (dry type separation). Low to high-pressure applications.

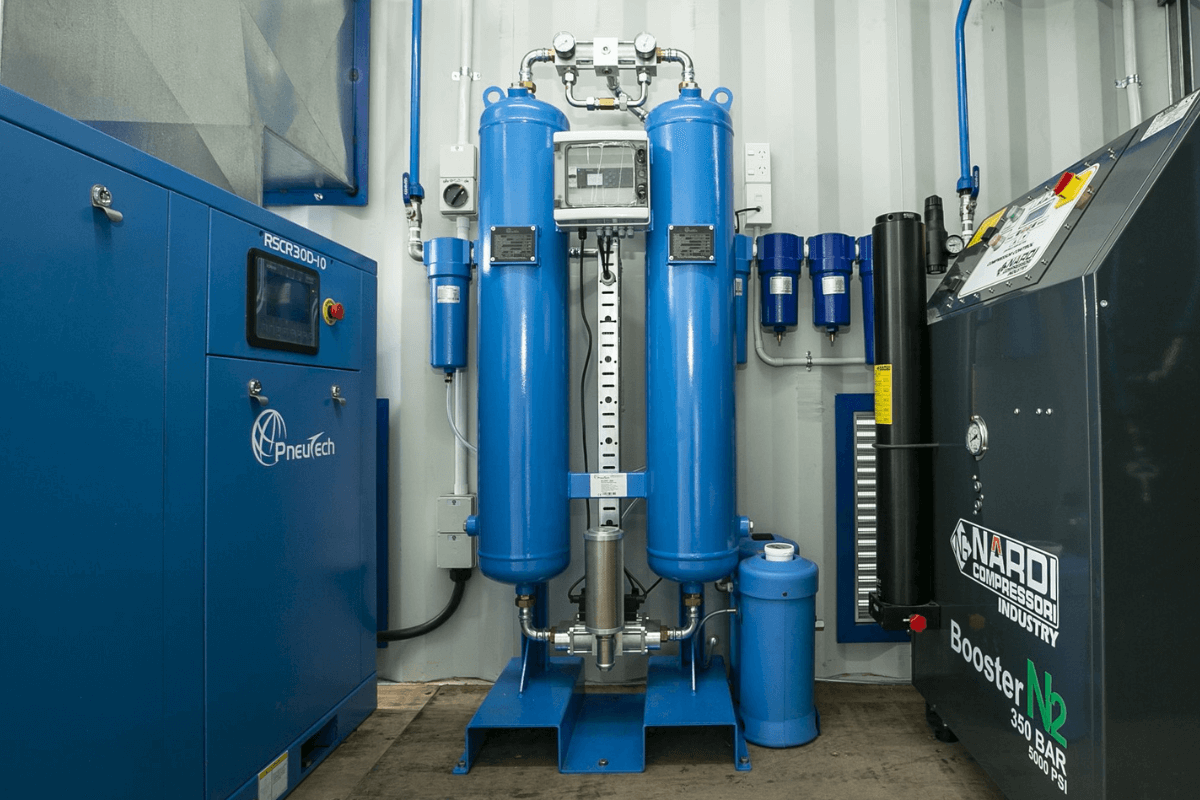

Industrial compressed air system for new hydraulic premises

South Canterbury Hydraulics is a Timaru-based business that has been providing hydraulic and hose fitting services since 2009. They approached us as they were moving to a bigger site that required a new compressed air system throughout the entire building.

View case study

The friendly Industrial Air Systems team are here to help! Contact us now with your compressed air request and we'll be back in touch by phone or email, as soon as possible.

Excellent service. Your guys have all been very, very good. You were willing to work around our production needs and come out in the middle of the night to get amongst the rats!

We’ve been staying with these guys because they have the right skills and experience.

Top-rate service. I would recommend your company. I hope we get Paul every time!

We had an issue with the compressor which these guys fixed. We’re very pleased with Industrial Air Systems. They reacted quickly, kept the unit running while a part was sourced and then fixed it quickly. When we’re looking at any upgrades Industrial Air Systems will be our first port of call.

You ticked all the boxes. Your guys were great. You come in, do the job and leave a pack of biscuits!

Paul has done a very nice job installing the pipework, it looks awesome. I’m glad that you recommended the aluminium pipe.

We have found Industrial Air Systems very good to deal with and very professional. Good service at a good price. I would not hesitate to recommend Industrial Air Systems to any company considering using them.

[Your tech] is a great guy to work with, he has great knowledge with all the gear and is always there when we need him. All the guys here at VIP love working with him.

We have had a good experience working with Industrial Air Systems – they are easy to do business with and we have no hesitation recommending them to companies wanting an efficient and economical supply for compressed air.

We have found their service team very responsive and excellent to work with, and from our good experience we would recommend Industrial Air Systems to any company requiring compressed air in the future.

We are very happy with the airlines and the setup. The whole process was easy and we received great communication from you and the team. Your contractor was also great to deal with and did a very tidy job of the install.

Industrial Air Systems NZ © 2026