Feeling the pressure of the CO₂ shortage? With prices skyrocketing in the past year, many brewers are looking for a viable alternative.

Fortunately, switching to nitrogen creates a cost-saving solution, while still producing high-quality beer. This article discusses how an on-site nitrogen generator can help you to reduce costs and keep your operations running smoothly now, and into the future.

The CO₂ shortage in New Zealand

CO₂ is commonly used in the preservation of fruits, vegetables, grains, and of course – beer brewing. However, the recent closure of the Marsden Point Oil Refinery is causing a shortage of the gas in the country. In the last six months alone, the cost of CO₂ has tripled.

New Zealand’s only remaining CO₂ supplier is Todd Energy in Taranaki, which is temporarily closed to fix an ammonia leak. The closure has highlighted how stretched our CO₂ supply has become, with many breweries forced to halt production.

"This is our peak time of the year. It's summer, it's beer-drinking weather and we can't package beer. It's a disaster." – Jos Ruffell, Garage Project co-founder

Nitrogen as a CO₂ replacement

Fortunately for our brewers, nitrogen is a cost-effective alternative to carbon dioxide. It is commonly used throughout the beer brewing process for various purposes:

- Nitrogenation

- Packaging

- Transportation

- Purging equipment

- Tank blanketing

- Forced carbonation

- Maintaining pressure in dispensing systems

- Homogenising

- Inerting to protect sensitive ingredients

Unlike carbon dioxide, nitrogen is readily available and easy to access, directly from the atmosphere.

What is an on-site nitrogen generator?

In light of the carbon dioxide shortage, many brewers are turning to nitrogen as a more viable solution. By investing in an on-site generator, you can produce your own nitrogen and cut costs dramatically.

An on-site generator produces the gas you need on the premises, rather than being delivered in cylinders. They are efficient, cost-effective, and environmentally friendly, providing a reliable source of gas without the need for frequent deliveries. We explain the advantages of onsite generators in detail below.

Unlimited supply

Unlike CO₂, nitrogen is not affected by shortages or supply chain disruptions. It makes up approximately 78.08% of the Earth’s atmosphere, while carbon dioxide accounts for less than 0.04%. What’s more, an on-site generator means you can produce nitrogen on demand. While others in the industry are concerned about limited gas supply and delivery delays, your brewery can operate without interruption.

No reliance on a third party

An on-site generator eliminates the need for a third-party supplier, as the gas is produced directly on the premises. This ensures a consistent and reliable source of nitrogen and protects your brewery from supply shortages, price spikes, or delivery disruptions.

Less wasted gas

Unlike tanks or cylinders, an on-site generator can produce the exact amount of nitrogen that is required. The generator can be adjusted to match fluctuations in demand, ensuring that an optimal amount of nitrogen is produced at all times. This reduces gas waste, helps to lower costs, and improves efficiency.

Lower costs

Using an on-site nitrogen generator can improve your bottom line and help your brewery control its expenses. That’s because of the low production costs, reduced waste, more efficient operations, and lack of delivery fees which collectively help to lower your running costs.

Reduce your carbon footprint

An on-site nitrogen generator will also reduce your brewery's carbon footprint. This is due to lower energy consumption, reduced waste, localised production, and improved sustainability. In stark contrast, carbon dioxide is a greenhouse gas produced by the burning of fossil fuels.

Making the switch to a nitrogen generator

Our range of PneuTech nitrogen generators offer exceptional results for both large and small-scale operations. Available in various packages, nitrogen generators are a cost-effective investment with low operating costs – ideal for breweries. To keep your nitrogen generator functioning optimally, simple maintenance and proper compressed air treatment are all it takes.

At Industrial Air Systems, we offer three types of generator setups – skid-mount, containerised, and factory-install.

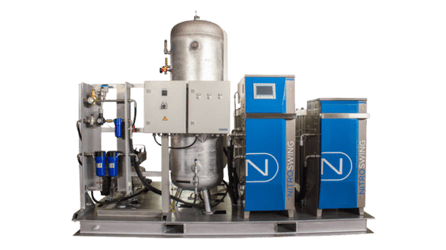

Skid-mount nitrogen generators

These systems come mounted on a skid for easy installation at your brewery's premises. They are compact, can be easily integrated into your existing processes, and are cost-effective.

See our skid-mount generators >

Containerised nitrogen generators

These systems are housed in a shipping container for easy transport and installation. They are self-contained and ideal for remote locations or areas with limited space.

See our containerised generators >

Factory-install nitrogen generators

Custom-designed to fit your plant layout and application, these generator systems are designed specifically for your needs. Our team will manage everything for you from the testing to full installation.

See our factory-install generators >

At Industrial Air Systems, we can provide you with a nitrogen generator tailored to your brewery's needs. With regular maintenance, you can enjoy years of use from your investment.

Reach out to our team today to learn more about switching to nitrogen and to request a free no-obligation quote for your business. Or find the appropriate generation package for your brewery in our helpful brochure below.

.jpg)