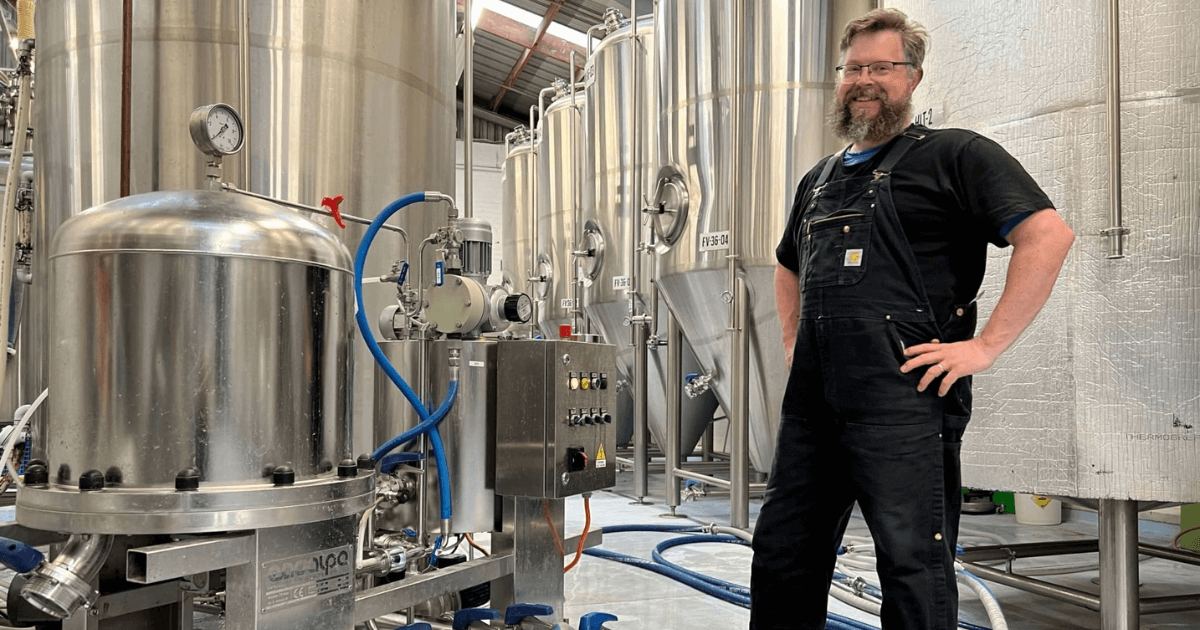

With expertise in engineering and compressor services, we provide on-site inspections, audits of compressed air systems, and complete factory fit-outs, making us the perfect partner for your business's compressed air needs. Our specialist technicians become an extension of your team, bringing international resources from the renowned PneuTech Group to source the best compressors worldwide. Our New Zealand-based experts are here to consult with you and find the ideal solution tailored to your unique requirements.

.png)

.jpg)