If you haven’t already heard, New Zealand is experiencing a major carbon dioxide (CO₂) shortage. And, while CO₂ has been the first choice for many industries in the past, many businesses have been forced to look at alternatives.

In this article, we explain how the CO₂ began, how it could impact your business, and what you can do about it.

The CO₂ shortage NZ

Found in the atmosphere, CO₂ is commonly used in various applications. Unfortunately, CO₂ is also a greenhouse gas and one of the biggest contributors to global warming. While many producers have depended on CO₂ for a variety of applications, this has all changed in the past year, especially in New Zealand.

In early 2022, one of New Zealand’s biggest producers of CO₂, Marsden Point Oil Refinery, was closed. This left the country with one remaining CO₂ producer – Todd Energy in Kapuni, Taranaki. The plant usually supplies 2,000 tonnes of liquid CO₂ every month for use in:

- Healthcare

- Dairy products

- Engineering

- Food packaging

- Carbonating beverages

- Pulp and paper processing

- Greenhouses

- Meatworks

Unfortunately, an ammonia leak required investigation at the end of 2022 and the Kapuni plant was temporarily closed. What was meant to be a quick fix for a faulty valve has now taken over 5 months. The final stages of repairs are complete and production was back at full capacity on the 1st of June.

The Government is working with affected industries to investigate the feasibility of another site for domestic production. During this process, UK industry experts have been consulted following a similar supply chain disruption in 2022.

How does the CO₂ shortage impact various industries?

The shutdowns led both small and large businesses to halt production and scale back, with CO₂ prices rising as much as eightfold from some distributors. In some cases, prices rose more than 500% in one week and supplies later dropped 50% to 60% below demand.

Unfortunately, importing CO₂ can cost 10 times as much due to shipping, overseas production costs, and demand. What’s more, the long lead time and transport chain into the country have left many businesses in the lurch for months. Many companies are struggling with production planning as a result of uncertain availability.

Freight

Dry ice, which is frozen CO₂, is often used to transport fresh produce, dairy products, vaccines, and even bees. It helps to keep freight chilled during export, making it possible to sell a large portion of New Zealand’s products to large buyers like China.

As a result of the shortage, dry ice prices rose from $3 per kilogram to $25. Freight forwarders were forced to import it from Australia to meet overseas contracts and cancel large numbers of shipments.

In some cases, companies couldn’t source any dry ice at all. Simon Dedman, Managing Director of Kuehne and Nagel, estimated some weeks saw 40 to 50 ships disrupted. This inability to get New Zealand’s primary produce on the shelves in consumer markets like China means other countries can fill the demand instead.

Agriculture

CO₂ is often used to boost plant growth and control pests in agriculture. Globally, the largest consumer of CO₂ is the fertiliser industry, where 130 Mt (million tonnes) of CO₂ is used in urea manufacturing.

For the dairy industry, the shortage has triggered concerns about safe production and scheduled deliveries. Many exporters were forced to turn down requests, losing business to China and Europe.

MBIE and MPI also reported that multiple manufacturers were forced to stop production and take products offline. Tegel had to stop producing chicken nuggets due to the inability to access CO2. The company now has a new production process that "takes longer, it's less efficient and raises our costs".

Oil and gas

After the fertiliser industry, oil and gas is the second biggest consumer of CO₂, with a consumption of 70 to 80 Mt CO₂ for enhanced oil recovery. As the gas becomes more expensive, and oil resources become more scarce, prices are anticipated to climb.

Industrial and steel production

CO₂ is critical for welding, steel construction, and maintenance. The Heavy Engineering Research Association has warned the Government of the cost implications for building roads, buildings, and ports. Companies were forced to reduce production and cut exports to honour domestic contracts.

The shortage has been described as a "very real threat" to the steel industry as fabricators had up to a 500% cost increase. For some, the costs of CO₂ went "from five figures well into six figures".

Food and beverage

CO₂ is commonly used to package food and beverages because it helps to keep the product fresh. While supermarket groups have said there is no clear evidence of the shortage translating into higher food prices, relying on one food-grade CO₂ supplier is not sustainable.

According to Raewyn Bleakley, CEO of the NZ Food and Grocery Council (FCG), many CO₂ users are “really feeling the pinch”. This will have a flow-on effect on prices for a wide range of products.

Fortunately, nitrogen can be used as an alternative. By displacing oxygen, nitrogen is an effective and affordable way to slow spoilage.

Healthcare

The CO₂ shortage is also affecting several aspects of the health industry and could lead to loss of life. If the shortage continues, NZ Blood will not be able to transport blood and hospitals won’t be able to store organs safely.

Water treatment

MPI has also said that water treatment in both New Plymouth and Wellington will be severely set back. This would result in 350,000 people in Wellington and 59,000 in New Plymouth receiving boil water notices for a month.

Breweries

New Zealand breweries produce about 17 million litres of craft beer annually and CO₂ is commonly used during this process. As it has become more difficult and costly to source, many breweries were forced to close. Many supply agreements could not be fulfilled and overall trading fell 30% as a direct result of the shutdown.

General Manager for Waitoa Beer, Mark Davey, described it as a “kick in the guts” for many brewers, who have had to import supplies from South East Asia and stop taking new orders.

Fortunately, nitrogen is an alternative to carbon dioxide and is commonly used throughout the beer brewing process for the following purposes:

- Nitrogenation

- Packaging

- Transportation

- Purging equipment

- Tank blanketing

- Forced carbonation

- Maintaining pressure in dispensing systems

- Homogenising

- Inerting to protect sensitive ingredients

Can nitrogen replace CO₂?

Nitrogen is quickly becoming the go-to gas for several industries. By using an on-site nitrogen generator, you can produce gas on the premises to meet demand. This is more efficient, cost-effective, and environmentally friendly.

Unlimited supply

Nitrogen occupies approximately 78.08% of the Earth’s atmosphere, compared to carbon dioxide which accounts for less than 0.04%. Additionally, an on-site generator allows you to source nitrogen on demand so you never have to worry about national supply shortages.

No third party

With an on-site nitrogen generator, you no longer need a third-party supplier. Instead of waiting for cylinders to be delivered, you can produce gas on the premises whenever you need it. This is more consistent and reliable and protects your equipment and operations from price spikes or disruptions.

Less waste

Unlike cylinders, an on-site generator produces the exact amount of nitrogen you require. It can be adjusted to match demand and ensure the optimal amount of gas is produced which reduces gas waste, lowers costs, and improves productivity.

Lower costs

Lower production costs, reduced waste, and increased efficiency mean an on-site nitrogen generator helps control your operational costs. With no delivery fees, it’s easier to plan your expenses.

Reduced carbon footprint

While carbon dioxide is produced by burning fossil fuels, on-site-generated nitrogen is a sustainable option. It consumes less energy, reduces waste, and localises production.

Industrial Air nitrogen generators

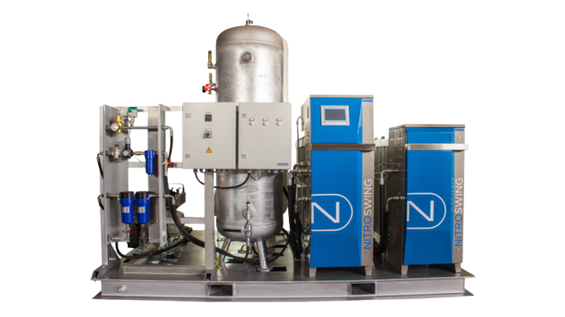

Our range of PneuTech nitrogen generators is available in three configurations – skid-mount, containerised, and factory-install.

Skid-mount nitrogen generators

These generators come mounted on a skid for easy installation. They’re compact, cost-effective, and can be easily integrated into your existing processes.

See our skid-mount generators >

Containerised nitrogen generators

These generators are stored in a shipping container for easy transport and installation. They are fully self-contained and perfect for remote locations or small spaces.

See our containerised generators >

Factory-install nitrogen generators

These generators are fully customised to fit your plant and application. Our team will take care of everything for you from the testing to installation.

See our factory-install generators >

Reach out today to request a free no-obligation quote for your business or download the full brochure to find the right generator for your needs.

.jpg)