The right compressed air piping ensures your compressed air system can operate efficiently. To ensure your piping is suitable for your application, we can help.

In this article, we explain which types of air piping are best for compressed air systems, covering materials and the best compressed air piping available in New Zealand.

Types of compressed air piping

The quality of your compressed air and the running costs of your system are influenced by the type of material used for your piping. Some materials can be corroded by lubricants used in the compression process, leading to leaks and particulates in the airflow.

Additionally, some materials can add unnecessary friction and cause the air pressure to drop in the pipes, causing inefficiencies and leading to costly repair callouts. Therefore, we recommend a non-corrodible, low-friction material like steel or aluminium.

Stainless steel pipe

Stainless steel is an alloy of chromium and steel. The chromium content provides enhanced corrosion resistance because it oxidises quickly and produces a stable, passive oxide film on the exposed surfaces.

- Corrosion resistant

- Durable and strong

- A high level of air purity

- Suitable for food applications

- Heavy

- Time-consuming installation, unless using press-fit technology

PE pipe

PE piping is another common choice for low-pressure compressed air systems due to its low cost. However, PE pipes do not last well over time and tend to sag between connections. These bends become moisture traps and allow the compressed air to pick up water as it passes through. Even with a refrigerated dryer, this will result in some moisture reaching your end-use.

- Low upfront cost

- Prone to slumping joints

- Moisture build-up in the airflow

- Reduced airflow may require sizing up

PVC pipe

PVC stands for Polyvinyl Chloride and it is inexpensive, easily accessed, and easy to install. However, PVC piping is plastic so it can be prone to cracking. Therefore, PVC pipes are not durable enough to withstand high pressures over a long period as they will become brittle, break, and even shatter.

Because of these safety risks, many countries have already banned the use of PVC piping for compressed air systems. Fortunately, there are safer and more durable options on the market that can be used for compressed air systems, such as aluminium. If you are currently using a PVC compressed air system, we recommend looking to replace it as soon as possible.

- Low upfront cost

- Easy to install

- Prone to cracking and shattering

- Safety risks

- Banned in some countries

Aluminium pipe

Aluminium is known for its reliability and durability. It won’t degrade or corrode, it’s flexible, and it’s incredibly lightweight, making it an ideal choice for compressed air piping. Additionally, most aluminium pipe is supplied ready to use so it doesn’t require much preparation, apart from cutting to size.

- Corrosion resistant

- Durable and strong

- Flexible

- Cleaner air

- Reduced energy costs

- Lightweight and easy to install

Compressed air pipe NZ

Here at Industrial Air Systems, we recommend opting for aluminium in your compressed air piping system. Not only is it long-lasting and corrosion-resistant, but it also provides a high level of air purity for your application.

Alu Air piping NZ

Alu Air piping is manufactured from aluminium to provide durability and corrosion resistance in your compressed air system. The Alu Air system ensures superior compressed air reticulation, resulting in a high-performance, long-lasting, and reliable solution.

20m x 10m Ring Main

The smaller of these three options, this loop piping system is suitable for smaller plants with 6m to 8m stud height, based on the height of the ring main. With four droppers, this system is great for smaller applications. Key characteristics include:

- The ring main measures 20m long by 10m wide.

- 25mm aluminium piping for the ring main.

- 20mm droppers with double outlet terminal points and moisture drains.

- 8 high-flow couplers (air outlets).

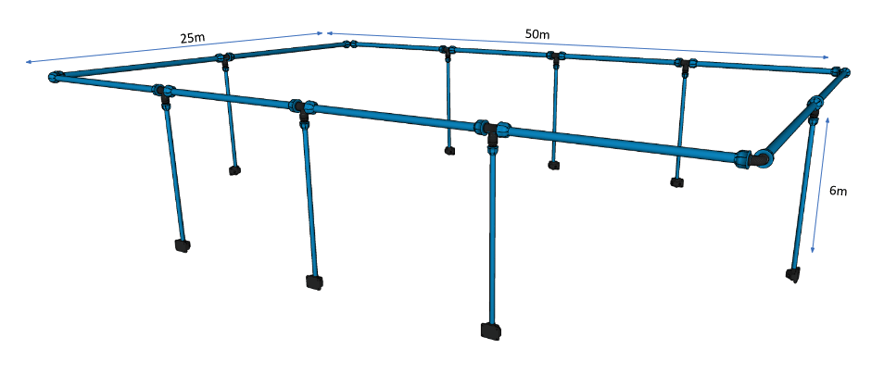

50m x 25m Ring Main

This loop piping system is suitable for medium plants with 8m to 10m stud height, depending on the height of the ring main. With eight droppers, this system can supply multiple operational demands with even pressure. Key characteristics include:

- The ring main measures 50m long by 25m wide.

- 32mm aluminium piping for the ring main.

- 25mm droppers with double outlet terminal points and moisture drains.

- 16 high-flow couplers (air outlets).

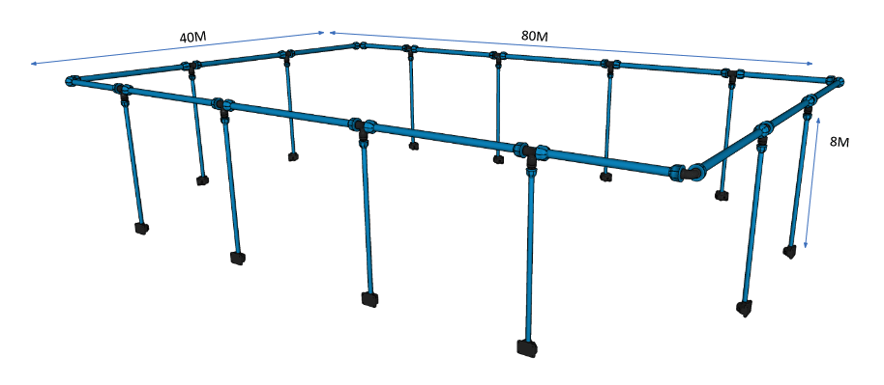

80m x 40m Ring Main

This looping pipe system is suitable for large buildings with 8m to 10m stud height, depending on how high the ring main is placed on the wall. With twelve different droppers, this system is ideal for serving numerous operational needs whilst maintaining steady pressure throughout. Key characteristics include:

- The ring main measures 80m long by 40m wide.

- 40mm aluminium piping for the ring main.

- 25mm droppers with double outlet terminal points and moisture drains.

- 24 high-flow couplers (air outlets).

Before you decide on an air piping system, discuss your options and requirements with our industry experts. We can answer any questions you may have and identify the capabilities you need most in your daily operations.

To see more air piping systems, you can find all the technical information and product listings from Alu Air by downloading our Alu Air piping brochure. Click the link below to get your free copy.

.jpg)