When looking for the ideal compressed air system, the price of your air piping will be an important factor. To help your decision, you need to consider the size, layout, materials, maintenance, and environment of your desired system.

To clarify the pricing of air piping systems, this article will explore five key determining factors, as well as estimated prices for a few standard piping setups. These rates include installation but are estimations only, so be sure to discuss your compressed air piping needs with an expert.

1. Piping dimensions

The size and amount of piping in your compressed air system will have a large impact on the overall price. That’s because the diameter and distance of the pipe influence the pressure at the point of use and if it isn’t carefully designed, could cost you in the long run.

Costly air pressure issues

Pipes that are too small for your required capacity or airflow pressure could result in unsafe levels at the end of use. Or, if your compressor is too far from the point of use, the pressure will drop too low and cause operational problems. For example, you risk sustaining premature machine wear leading to increased maintenance costs.

An increase in pressure at the compressor discharge can also drive up the cost, with an increase of as little as 2 psi requiring 1% more energy to run. To avoid this, your compressor should be kept within a reasonable distance from every point of use and the compressor pressure should never exceed 10% of the discharge pressure.

Installation and maintenance costs

Installation time is another factor to consider when determining the amount of air piping you need. The more piping you install, the more time it will take to assemble the system and maintain it. To keep costs low, you should use only the required amount of air piping you need to effectively complete the job.

2. Environmental factors

When designing a compressed air system, you have to consider the environmental impacts it will operate within. If not considered, you risk losing pressure or increasing maintenance costs so it’s a critical step.

Plant temperature

The temperature of your plant will have a significant effect on the efficiency and running costs of your air system. For large plants, it’s likely for pipes to move throughout different rooms, underground, or even outside. To keep costs low and your employees safe, you need to ensure your pipes can withstand temperature fluctuations and are safe from freezing, burning, corrosion and wear and tear.

Obstacles within the space

If your piping system needs to work around existing obstructions, you should expect the cost of your pipes to increase. If your plant has roller doors or purlins, you may require more pipes and fittings to accommodate them. The pricing could quickly increase depending on how many extra elbows or unions are required for your piping system.

3. Layout

There are two primary options when laying out your air piping, these are known as looping and straight – the one you choose will influence the running costs.

Looping piping systems also referred to as ‘ring-main’ systems are laid out in a loop around the plant, with air flowing around it and dropping down into each point of use. These are best suited to plants with relatively square shapes and provide an even distribution of air throughout.

Straight piping systems or ‘linear’ layouts consist of one main pipe leading up the middle with several secondary pipes branching off towards each point of use. These are generally less expensive and sometimes more efficient, particularly for plants that are long and narrow.

By using the wrong piping layout for your plant’s design, you will certainly experience pressure drops and incur unnecessary piping costs. That’s why it’s always best to consult an expert when determining the layout of your piping system.

Example of a looping or 'ring main' piping setup.

4. Materials

The materials used for your piping system are another key determinant of the quality of your compressed air and the running costs of your piping. Some piping materials can be corroded by lubricants used in the compression process which leads to leaks and particulates in the air stream. Not only that, the composition of your pipes can add unnecessary friction and cause the air pressure to drop, causing inefficiencies and expensive maintenance callouts. To avoid this, you should opt for a non-corrodible, low-friction material like copper, steel, or aluminium.

5. Maintenance

When installing a compressed air system, you need to consider the ongoing maintenance costs required to keep it going, including for your piping. The quality of your piping system will have a huge influence on the amount of time and money spent on maintenance. Aluminium is easier to cut, install, and maintain, meaning you’ll spend less time on maintenance and require fewer fixes in the long run.

When maintenance needs to be done, it’s essential to have a bypass pipe and valve ready to continue your operations smoothly. This can also help when expanding your operations because new piping can be easily installed without causing any major disruptions. Therefore, you will save money long-term by investing upfront.

Prices for Alu Air piping setups

All piping systems are unique, depending on the plant design and operational requirements, but the following three Alu Air systems are a great place to start. Alu Air piping is manufactured from aluminium to provide superior durability and corrosion resistance. The Alu Air system ensures the ultimate compressed air reticulation, resulting in a high-performance, long-lasting, and reliable solution.

To help you understand the pricing of the Alu Air system, let’s discuss the estimated pricing of each of the following piping setups.

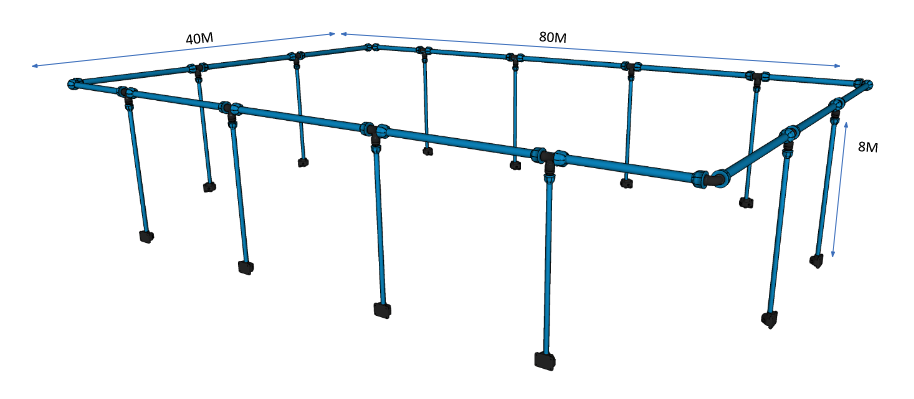

80m x 40m Ring Main

The largest of these three systems, this looping piping system is suitable for large buildings with 8-10m stud height, depending on how high the ring main is placed on the wall. With twelve different droppers, this system is ideal for serving multiple operational needs while still maintaining even pressure throughout.

Key characteristics

- The ring main measures 80m long by 40m wide.

- 40mm aluminium piping for the ring main.

- 25mm droppers with double outlet terminal points and moisture drains.

- 24 high-flow couplers (air outlets).

With these features in mind, the total cost of this system could range from around $22,000-32,000 +GST.*

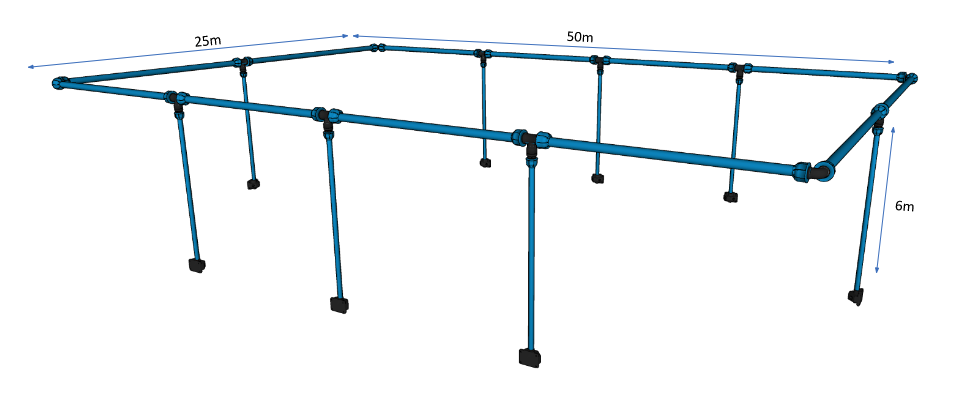

50m x 25m Ring Main

This loop piping system is suitable for medium plants with 8-10m stud height, depending on the height of the ring main. With eight droppers, this system can serve numerous operational demands with even pressure across the board.

Key characteristics

- The ring main measures 50m long by 25m wide.

- 32mm aluminium piping for the ring main.

- 25mm droppers with double outlet terminal points and moisture drains.

- 16 high flow couplers (air outlets).

With these features in mind, the total cost of this system could range from around $11,300-20,000 +GST.*

20m x 10m Ring Main

The smaller of these three options, this loop piping system is suitable for smaller plants with 6-8m stud height, based on the height of the ring main. With four droppers, this system is great for smaller applications.

Key characteristics

- The ring main measures 20m long by 10m wide.

- 25mm aluminium piping for the ring main.

- 20mm droppers with double outlet terminal points and moisture drains.

- 8 high flow couplers (air outlets).

With these features in mind, the total cost of this system could range from around $4,380-8000 +GST.*

Before you commit to an air piping system, you need to discuss your options and requirements with industry experts. Our experienced team at Industrial Air Systems can answer any questions and pinpoint the capabilities you need most for your operations.

If you would like to see more air piping systems to decide which is best suited to your needs, you can find all the technical information and product listings for our Alu Air systems by following the link below.

*The prices included in this article are estimates and should be used as a guide only. For accurate pricing please get in touch with us to request a quote.

.jpg)