Whether you run a workshop or a food manufacturing operation, there are now such a vast range of air compressors available that it can be hard to decide just which air compressor is right for you and the job at hand. One of the options to consider when you go to purchase a new air compressor is whether you should choose an oil-lubricated air compressor or an oil-free air compressor.

While both types of air compressor serve the same purpose – to produce compressed air and transfer this air to power different types of machinery, just which type of air compressor you use will come down to the application that you’re using it in. Different industries will have different requirements for compressed air, and more specifically, the purity level of air that’s being produced.

Read on to find out the main differences between oil-free and oil-lubricated air compressors, and why you would choose one compressor over the other.

The differences between oil-lubricated and oil-free air compressors

Oil-lubricated air compressors and oil-free air compressors each have their own significant benefits which can make all the difference to your workshop or factory, depending on what you will need to use the air compressor for.

In essence, an oil-lubricated air compressor uses oil to lubricate the compressor, seal the air, and also keep it nice and cool. An oil-free air compressor is the opposite in that it doesn’t use oil to lubricate the different parts inside the air compressor. An inter-cooler is then used to keep heat down (instead of oil).

Benefits of an oil-lubricated air compressor

As an oil-lubricated air compressor uses oil to operate, it naturally needs regular checks and oil changes to ensure that everything is working correctly. This type of regular checking will mean that naturally, oil-lubricated compressors will receive more maintenance than oil-free compressors. This can prove beneficial in the long run as regular maintenance could mean the difference between your air compressor running efficiently, or breaking down.

Another benefit to oil-lubricated air compressors is that they generally produce less noise as well as heat. This is simply down to the fact that the air compressor is lubricated with oil so naturally won’t be as noisy. Oil also helps to draw heat away from the compression while the air compressor is running which ensures that the machine is as cool as possible.

Benefits of an oil-free air compressor

One of the main benefits of an oil-free compressor is that it doesn’t cause any contamination. Businesses that operate in food and beverage, and medical industries rely on clean compressed air for manufacturing purposes so having access to an oil-free air compressor that produces clean air is an essential component. The medical and dental industry also further relies on oil-free compressed air when it is being used for human consumption. You don't really want a lung-full of oil contaminated air when you visit the dentist!

The air purity classes

As we know, compressed air is used to help manufacture a wide range of products which includes products from the food and beverage, medical and even electronics industries. These types of products in particular cannot be contaminated during the manufacturing process as this would then have adverse effects on the end result of the product which could then result in lost money, and business. Manufacturers cannot risk even the smallest amount of a foreign substance (like oil) getting into their products so need to ensure that from the outset, they’re using the best products to ensure no contamination.

Traditional air compressors that are oil lubricated simply won’t cut it for these types of manufacturing processes, which is why an oil-free compressor is required. Oil-free air compressors must still meet a certain standard however, and ensure that the compressed air produced is oil-free.

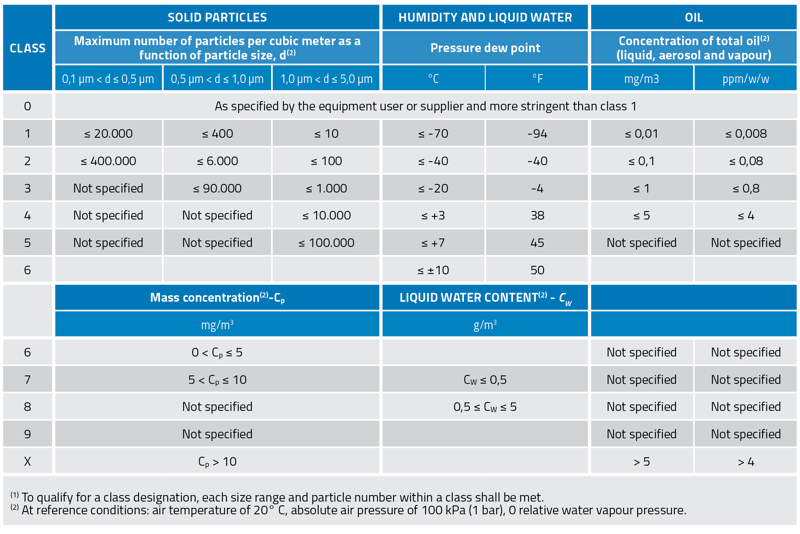

The International Standards Organisation (ISO) has created a set of international standards specifically for compressed air. Depending on the purity level of the compressed air, compressed air free from oil will receive an ISO ranking between 0-5. Class 0 being the cleanest and most pure class of air.

The ISO compressed air quality standards.

Due to its use in industries that manufacture things like food and pharmaceuticals, an elevated level of filtration is required so that no contamination from oil occurs. If you operate in these industries it's recommended that you use an oil-free air compressor and filtration to produce the cleanest air possible to safeguard against any possible contamination.

RSCRD-V Series Oil-Free Compressors

If you're on the hunt for an oil-free air compressor or you would simply like to replace your existing compressor with something that can provide clean air, then we would encourage you to take a look at the range from PneuTech.

PneuTech’s RSCRD-V series oil-free compressors produce the cleanest and highest purity level of oil-free air to guarantee food safety. With the 100% oil-free Class 0 certification, there is no need to worry about oil contamination testing – the RSCRD-V eliminates all traces of oil contamination from the air supply at the source.

Combining variable speed drive technology with superior two-stage air end and tough Teflon-coated rotors, the PneuTech oil-free series provides peace of mind for any food-grade production facility. Along with this peace-of-mind you will also see significant energy savings of up to 40% from the variable speed drive – you’ll only pay for the compressed air that you use!

Get in touch with us today to learn more about the PneuTech range and to see why the RSCRD-V series are fast becoming a status symbol for safety and technology! Our friendly team will work with you to find the right model that fits your exact needs.

.jpg)