When oil contamination can ruin products, halt production, and damage your reputation, the purity of your compressed air matters. Oil-free compressors offer the solution many industries need, providing clean, uncontaminated air without sacrificing performance.

But what makes these specialised machines different from standard compressors? The answer lies in clever engineering that eliminates the need for internal lubrication while maintaining efficiency and reliability.

What is an Oil-Free Air Compressor?

An oil-free air compressor does not use oil to lubricate the different parts inside the compression chamber. This fundamental design difference allows it to produce high-quality, contaminant-free air for applications where purity is essential.

What makes these systems particularly valuable is their ability to achieve the highest air purity standards. Many oil-free compressors are certified to meet ISO 8573-1 Class 0 requirements, the most stringent air quality classification in the international standard. This certification is crucial for applications where even microscopic oil particles could damage products or compromise safety, such as food processing, pharmaceutical manufacturing, and electronics production.

Read more about the benefits of oil-free compressors >

How Oil-Free Compressors Work

Oil-free compressors rely on specialised materials and precision engineering to operate efficiently without internal lubrication. These innovative designs use alternative methods to manage friction and heat, ensuring reliable operation while delivering pure, oil-free air.

Compression Mechanisms

Different oil-free compressors employ various approaches to achieve oil-free operation:

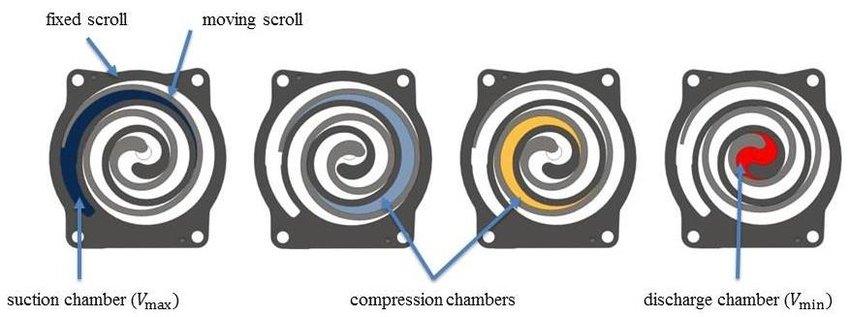

Scroll Technology

Scroll compressors use two interleaving spiral elements, one fixed and one orbiting. As the mobile scroll rotates, the air gets trapped at the inlet and is pushed toward the centre of the spirals. The spirals create increasingly smaller pockets that compress the air as they move, gradually increasing pressure without any metal-to-metal contact. This contactless design eliminates the need for lubrication within the compression chamber, resulting in completely oil-free operation.

Rotary Screw Systems

Oil-free rotary screw compressors utilise precision-engineered rotors coated with special materials that prevent metal-to-metal contact. Carbon ring seals create effective barriers between the compression chamber and any parts requiring lubrication. These sophisticated sealing systems entirely separate the air path from lubricating components, ensuring no oil can contaminate the compressed air.

The rotors in these systems typically operate at high speeds with minimal clearance between components, creating an efficient compression process without relying on oil for sealing or cooling. Special cooling systems manage heat buildup, which is particularly important in oil-free designs where oil isn't available to absorb thermal energy.

Reciprocating Design

Reciprocating oil-free compressors rely on Teflon-coated pistons and cylinders to create a low-friction interface. These non-stick surfaces allow pistons to move freely without requiring liquid lubricants. The Teflon coating serves multiple functions: it reduces friction, prevents metal-to-metal contact, and creates an effective seal for air compression.

Many reciprocating designs also incorporate specialised piston rings made from self-lubricating materials that maintain their slick properties throughout thousands of compression cycles. Precise manufacturing ensures tight tolerances between components while allowing sufficient clearance to prevent contact and the resulting need for lubrication.

The Complete Process: From Air Intake to Compressed Air

1. Air Intake and Filtration

The compression process begins when outside air passes through an inlet filter system. This initial filtration step is crucial for oil-free systems because it removes dust and particles that might damage the internal components or compromise the special coatings that replace traditional oil lubrication.

The unloader valve opens to help the compressor draw air into its chamber, placing it in the "loaded" position. When the valve closes, the compressor enters the "unloaded" condition and begins running. Clean intake air ensures longer component life and helps maintain the integrity of the entire system.

2. First-Stage Compression

After filtration, air enters the low-pressure compressor element, where the first stage of compression occurs. Without oil to absorb heat, this process can generate significant temperatures, often reaching up to 180 degrees Celsius, considerably higher than oil-lubricated systems.

In a typical oil-free setup, this initial compression stage will operate at around 2.5 bar. The absence of flowing oil (which typically acts as a cooling medium) means that effective heat management becomes a critical design consideration.

3. Intercooling System

Following the first compression stage, the heated air passes through an intercooler. This crucial component reduces air temperature before further compression takes place.

Cooling compressed air serves two important purposes:

- It prevents heat-related damage to the compressor's components.

- It increases air density, allowing for more efficient compression in subsequent stages.

The intercooler also features moisture traps that remove condensation formed during the cooling process, ensuring cleaner, drier air moving forward in the compression cycle.

4. Second-Stage Compression

After cooling, the air moves to the high-pressure compressor element for final compression. This stage typically achieves pressures ranging from 8 to 10 bar (116 to 145 psig), depending on the specific model and application requirements.

As with the first stage, this process generates considerable heat that must be managed to ensure efficient operation and prevent component damage.

5. Aftercooling and Air Preparation

The final compressed air, now at high pressure and temperature, passes through a check valve (preventing backflow) and enters an aftercooler. This component brings the air temperature down to a usable level before storage or distribution.

Many systems also include pulsation dampeners located before the aftercooler. These devices reduce vibrations caused by the compression process, ensuring smoother operation and more consistent air pressure throughout your system.

6. Pressure Monitoring and Control

Once compressed, the air is stored in a receiver tank. Detection equipment monitors pressure levels and automatically activates the compressor when pressure falls below predetermined thresholds.

The pressure switch connects to the unloader valve, controlling the compressor's on/off cycling to maintain stable pressure levels. This automated system ensures a consistent air supply without requiring constant manual adjustment.

Cooling Systems: Managing Heat in Oil-Free Compressors

Without oil to absorb and distribute heat, oil-free compressors require alternative cooling methods to maintain optimal operating temperatures.

1. Air-Cooled Options

Smaller oil-free units typically employ air cooling systems. These designs feature fins and fans that draw heat away from compression elements. Air-cooled systems:

- Require less installation space.

- Work effectively in environments with good airflow.

- Need minimal maintenance.

- Ideal for portable or smaller applications.

2. Water-Cooled Designs

Larger industrial compressors often utilise water cooling circuits. These systems manage higher heat loads effectively by circulating water through dedicated cooling paths. Water-cooled compressors may feature:

- Separate cooling circuits for different compressor parts.

- More precise temperature control.

- Better efficiency in high-demand applications.

- Lower operating noise levels.

Specialised Materials: The Secret to Oil-Free Operation

To compensate for the absence of oil lubrication, oil-free compressors incorporate advanced materials and design features:

- Specially coated cylinder walls and pistons (often using Teflon or similar materials).

- Bearings designed to operate at higher temperatures with minimal friction.

- Precisely engineered components, manufactured to tighter tolerances.

- Closed lubrication systems for parts that never contact the compressed air.

These specialised materials enable oil-free compressors to deliver reliable performance while maintaining the highest air purity standards.

Oil vs Oil-Free Air Compressors: Which is Right for You?

Oil-lubricated and oil-free air compressors each have their place in modern industry. Understanding their fundamental differences helps you make the right investment for your specific application.

An oil-lubricated compressor uses oil to reduce friction between moving parts, seal compression chambers, and transfer heat away from working components. These traditional systems typically have longer operational lifespans and produce less noise during operation. However, they require regular oil changes and maintenance, which increases long-term ownership costs and creates potential environmental concerns from oil disposal.

In contrast, oil-free compressors eliminate oil from the compression chamber entirely. They rely on alternative methods to manage friction and heat, using advanced materials and design features to ensure reliability. While they might have higher initial purchase costs, the absence of oil changes and reduced maintenance requirements often results in lower lifetime expenses.

Applications Where Oil-Free Compressed Air is Essential

Air purity requirements vary dramatically across industries, with some applications absolutely demanding oil-free compression technology. Food and beverage manufacturers rely on contaminant-free air for processes ranging from packaging to ingredient aeration, where even microscopic oil particles could compromise product safety and trigger costly recalls.

Similarly, pharmaceutical and medical facilities must maintain stringent air quality standards throughout their operations. From laboratory environments to production facilities, these sensitive applications cannot tolerate any contamination that might affect medication efficacy or patient safety.

Electronics manufacturing represents another industry where oil-free air is non-negotiable. Circuit boards and microprocessors are particularly vulnerable to contamination, with even invisible oil residue potentially causing component failure or degrading long-term reliability.

Other industries benefiting from oil-free technology include:

- Textiles: Preventing permanent fabric staining during processing.

- Natural gas: Ensuring operational safety in extraction and processing.

- Plastics: Maintaining consistent quality in formed products.

- Woodworking: Protecting finishes from contamination.

- Plumbing: Testing systems with clean, uncontaminated air.

- Paint application: Delivering flawless finishes free from oil spots.

Premium Oil-Free Compressors from Industrial Air Systems

At Industrial Air Systems, we stock two superior series of oil-free compressors to meet diverse industrial needs throughout New Zealand.

PneuTech RSCRD-V Series

Our flagship PneuTech RSCRD-V series represents the cutting edge of oil-free compression technology. These variable-speed, rotary screw air compressors combine safety, durability, and exceptional performance in a package engineered for demanding industrial environments.

What sets these units apart is their 100% oil-free Class-0 Certification, guaranteeing the complete elimination of oil contamination at the source. This certification matters because it removes the need for air/oil separator changes or contamination testing, simplifying maintenance while ensuring absolute air purity.

The variable speed drive technology adapts to your actual air demands, dramatically reducing energy consumption during periods of lower usage. This intelligent design not only lowers operating costs but also extends component life by reducing unnecessary wear.

RSCRXA Scroll Compressors

For operations requiring reliable, cost-effective oil-free air, our RSCRXA range delivers exceptional value. These scroll compressors produce air to ISO 8573.1 standards with minimal maintenance requirements, making them particularly suitable for medical and food & beverage applications.

The integration of world-renowned Anest Iwata scroll air end technology elevates these units above standard offerings. Their silicone-free construction eliminates the need for inline filtration to remove hydrocarbons, while the absence of frictional components within the air chamber ensures pristine air quality without metal contaminants.

Practical advantages include remarkably quiet operation that doesn't require hearing protection, compact dimensions for flexible placement, and significantly reduced maintenance requirements compared to traditional systems.

Why Choose Oil-Free Technology?

Financial Advantages

While the initial investment might be higher, oil-free compressors often pay for themselves through:

- No ongoing oil purchases or disposal fees.

- Fewer filter replacements.

- Reduced energy bills.

- Streamlined maintenance routines.

- Reduced risk of product contamination and costly recalls.

Environmental Impact

For companies concerned with sustainability:

- No oil disposal or potential spills.

- Less waste from fewer filter changes.

- Lower carbon footprint from efficient operation.

- Cleaner workplace environment.

Practical Benefits

- Quick startup regardless of temperature (unlike oil-based systems that struggle when cold).

- Installation flexibility without worrying about oil levelling.

- Consistent air quality from day one to year five.

- Less technical expertise is required for maintenance.

- Reduced production downtime.

Get Your Free Oil-Free Compressor Guide

To find out more about oil-free air compressors and the benefits of our oil-free range, download our free brochure. You'll find all the details to select your compressor model, including product specifications and expert advice.

-2.png?width=400&height=400&name=Untitled%20design%20(4)-2.png)

.jpg)