Air compressors can be an expensive utility for businesses, which is why it’s important to find the most efficient option available. Air compressors are essential for many industries, including farming, hospitality, automotive, oil & gas, mining, contracting, manufacturing and medical. But between an electric compressor and its diesel counterpart - which of these is more efficient?

Unfortunately, there’s no simple answer to that question because the efficiency of an air compressor often depends on the availability of power and local energy costs. To help you to choose the best compressor for you, we’ve put together this blog outlining the pros and cons of both diesel and electric compressors. We've also outlined other important factors you may want to consider when choosing an energy-efficient compressor.

Pros and cons of diesel air compressors

Traditionally, diesel compressors have been the popular choice for a few reasons. Most significantly, diesel compressors are portable and do not require separate generators to run. That makes them incredibly useful for worksites in locations without a power source, such as isolated construction sites or sandblasting yards. Whilst diesel compressors have been historically wasteful and expensive to maintain, it is worth noting that the technology of these designs has been refined significantly in recent years. Due to the changing regulations for emissions, diesel compressors have been adapted to reduce waste, and require less work to maintain.

When compared to electric compressors, however, diesel compressors will never be as environmentally clean or as energy efficient because they require intensive servicing and they produce greenhouse gases. So while diesel compressors have been the traditional favourite, their popularity is in decline.

Pros of diesel air compressors:

- Portable and easier to use on non-powered sites.

- No trip hazards caused by electrical cords.

Cons of diesel air compressors:

- Requires frequent and expensive maintenance, as much as four times more than electric compressors.

- Needs ongoing licensing and WOF.

- Requires constant monitoring of diesel to ensure it doesn't run dry, resulting in expensive servicing to resume operation.

- Produce lower air quality due to higher condensation levels.

- Produces CO2, NOx and other pollutants which increase your business’s carbon footprint.

Pros and cons of electric air compressors

Electric compressors are growing in popularity for several reasons. In general, they are the most energy-efficient air compressor; they are also safer, less polluting, and more affordable.

Pros of electric air compressors:

- Smaller footprint than comparable output diesel compressor, no additional engine to power it.

- Variable-speed types are highly efficient, saving a lot of money over fuel costs.

- Produces virtually no emissions.

- Safer due to less hot parts, and no combustible fuel.

- Less expensive to buy and maintain.

- Simple routine maintenance because everything is built-in.

- Produces high-quality air.

- Plugs into a power supply which means no need to refuel.

Cons of electric air compressors:

- Requires a power source to plug into.

- Can only be used off-grid with a diesel generator.

- Electric cords can be a trip hazard.

Diesel prices rising

With our finite fuel resources depleting, diesel prices are set to rise dramatically over the next few decades. The price of diesel has already increased significantly in recent years, making it crucial for businesses to look into alternative options for fuelling their equipment. Electric power has been the main contender for alternative fuel and is quickly becoming the preferred option in many industries.

The government is also implementing policies which will make using electric power easier and more widely accessible, while diesel continues to become further out of reach. By making electricity more affordable, these changes will influence consumers and businesses to transition from fossil fuels to electricity wherever possible.

Because of this, electric compressors are far more economical to operate and service. In fact, a 185 cfm diesel compressor with a 102L fuel tank can cost two to four times more to operate than a 50-hp electric compressor. Paying less for fuel is the smart decision for businesses, especially when there’s no sign of diesel prices coming back down.

Reduce your carbon footprint

With the evolving climate crisis, it’s well worth investing in your business’s sustainability efforts. Policy changes regarding emissions reductions mean businesses must be ready to update their processes according to the new standards, and it can be a significant challenge to keep up. However, it’s worth adapting to these changes before they’re legally required so that your business can be prepared. By making adjustments early, you can avoid a pile-up of expenses, and be ahead of your competition. The climate crisis is going nowhere, which means your business will need to keep up, and in many cases, switching to electric power is a logical first step.

In the case of air compressors, the argument is no different. Electric compressors are the most efficient, and a more environmentally friendly option. If you are wanting to reduce your business’s carbon footprint and keep up with emissions regulations, electric compressors, in particular energy-saving variable speed types with permanent magnet motors, are the way to go.

Air quality

It goes without saying that air compressors must be capable of processing high-quality air. However, diesel compressors have no aftercooler which means the air being produced is hotter, and condensates downstream in the air systems. As a result, the air produced is less pure, and the compressor and down-stream equipment is more prone to corrosion, rust and breakdowns.

An electric compressor, on the other hand, is designed to produce quality air by using filters and dryers to refine it. Given that this is the primary goal of an air compressor, it’s well worth getting this step right.

Noise

Electric compressors are also far quieter than diesel compressors because they don’t have built-in engines. In fact, electric compressors can be up to five decibels lower than diesel models, which makes the work environment considerably safer and more comfortable. If you’re wanting to improve your workplace environment, reducing the compressor noise is a good place to start.

Servicing and maintenance

Regular maintenance of air compressors is important, but the duration and frequency are not the same for electric models when compared to diesel models. Diesel compressors are much more efficient to maintain than they used to be, however, due to having an engine, fixes can take a long time. On average, diesel compressors require a tank refill every 12 hours and filter changes every 250 hours, this is on top of licensing and WOF fees for trailer-mounted types.

On the other hand, electric compressors don’t have removable parts, and therefore need far less servicing. Because of this, intervals between servicing are four times as long as diesel compressors, which means less downtime and fewer repairs.

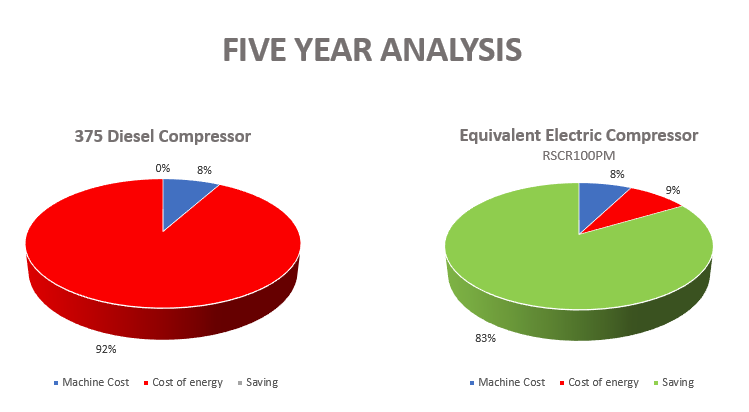

If you are looking for an efficient and economical air compressor, an electric model is likely the best option for you. Through a 5-year cost analysis of a 375 diesel compressor and an electric RSCR100PM compressor based on 2,500 operating hours per annum and indicative upfront cost of $60,000 each, we’ve demonstrated how impressive the savings difference can be. The electric compressor delivered energy savings of 83% compared to its diesel counterpart which means an estimated power saving of $618,175 (refer to the chart below). Therefore, electric compressors are less expensive to run, require far less upkeep, and reduce your carbon footprint all while producing high-quality compressed air.

For the full range of Industrial Air Systems’ electric air compressors, download our free air compressor catalogue. You’ll find all there is to know about our energy-efficient rotary compressors, and how to optimise your compressed air system for the best possible results.

.jpg)