Nitrogen (N₂) is commonly used as a preferred assist gas for laser cutting and can perform all cutting operations. Because it is inert, N₂ gas effectively removes unwanted and contaminated gases including oxygen, resulting in a higher quality and cleaner cut result.

The laser-cut components are free from tarnishing and oxidisation, which also makes them ideal for welding.

Clean & dry laser machine protection

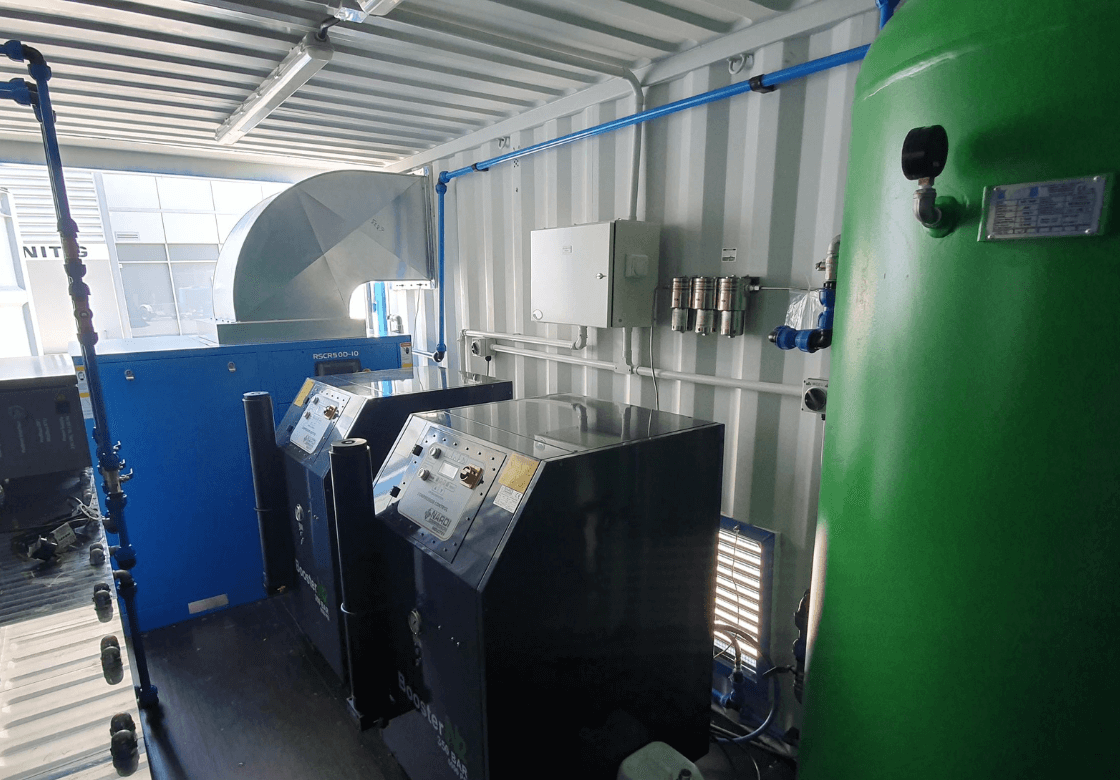

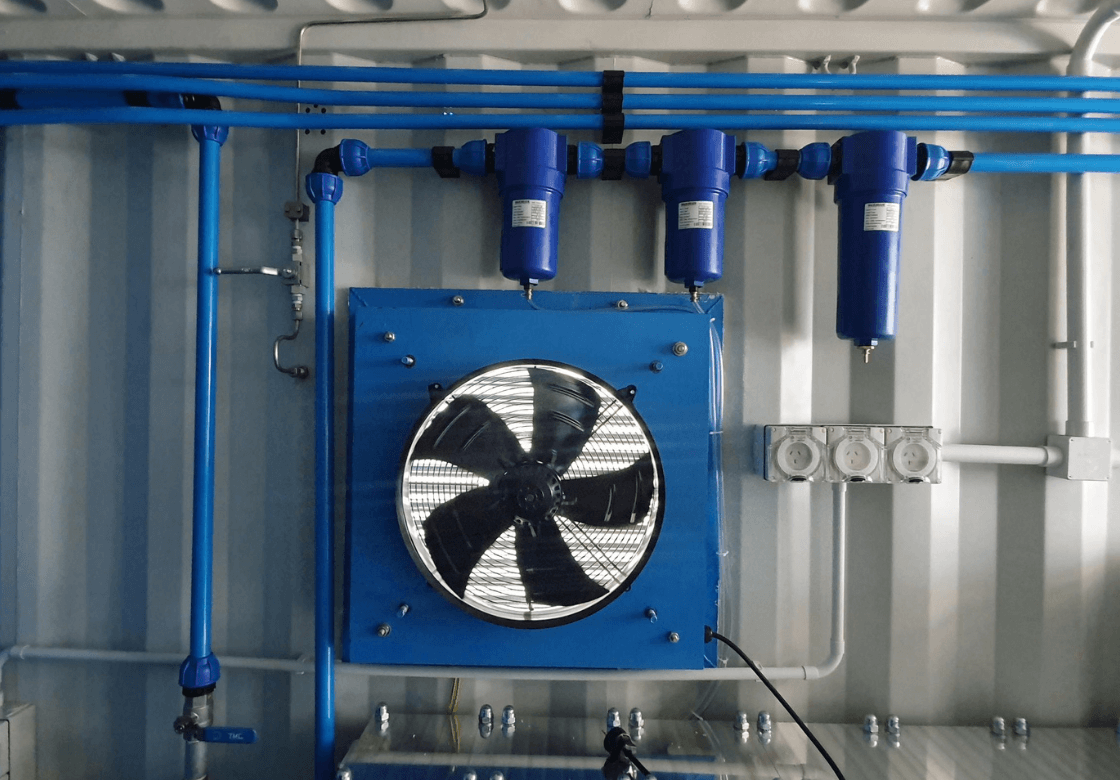

The Nitropak incorporates a 7-stage low and high-pressure filtration system which separates out any oil contamination down to 0.01 microns. An additional large carbon tower also serves as an oversized safety barrier to absorb even the smallest trace of oil should any of the previous four filters fail.

Multi-stage filtration protects and safeguards the laser cutting head and electronics from premature wear or failure while providing for good clean cutting.

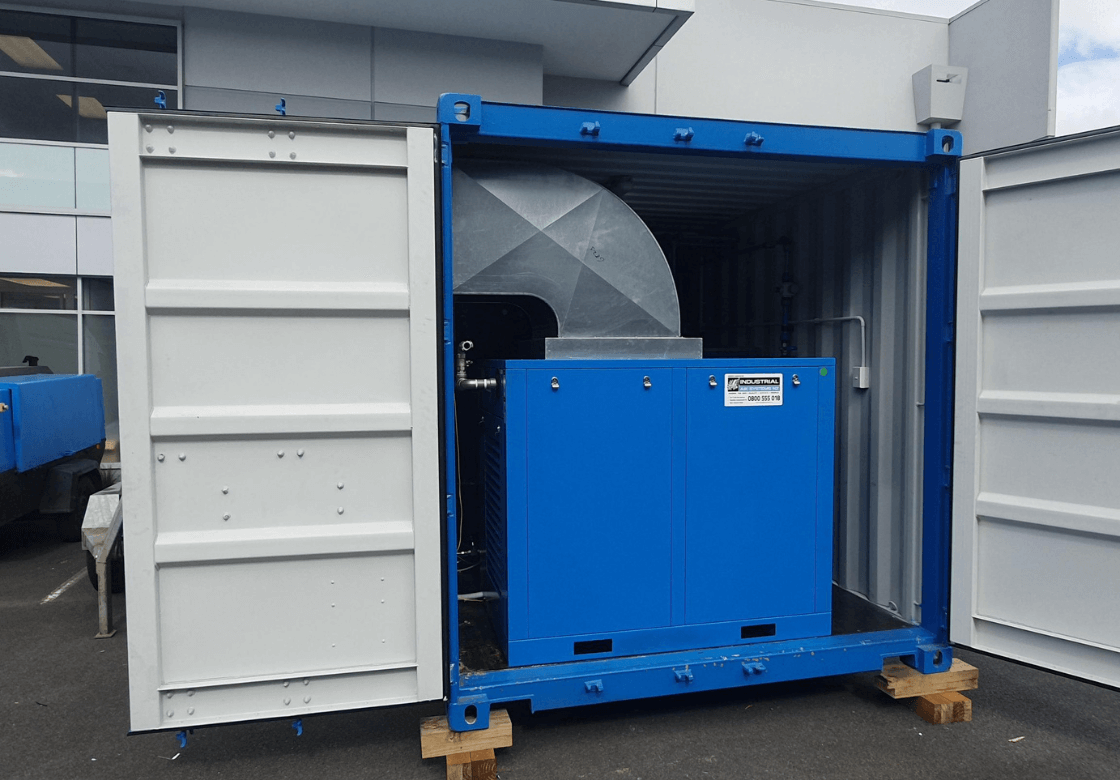

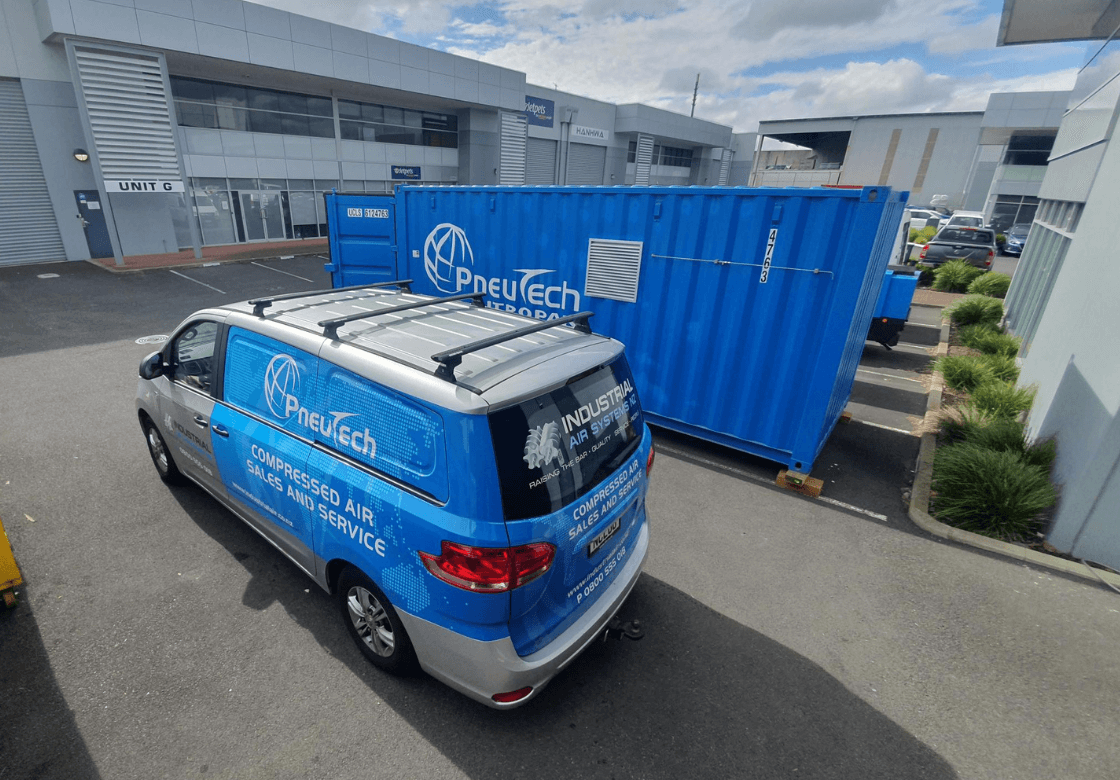

Nitropak setup with multi-stage filtration.

Nitropak setup with multi-stage filtration.

Fail-safe pure laser cutting

The general purity requirement for laser cutting stainless steel and aluminium is 99.99% or 0.01% contamination (100ppm).

The Nitropak will deliver gas from 97 to 99.999% purity (10ppm) as required, which is very clean and dry. The Nitropak incorporates a real-time oxygen monitor that not only reads and controls the purity level to the exact setting required but also alarms if for any reason the purity drops. This prevents inconsistent gas from being delivered to your laser cutter.