Need to contact us?

The friendly Industrial Air Systems team are here to help! Contact us now with your compressed air request and we'll be back in touch by phone or email, as soon as possible.

We supply high-quality air receivers for all compressed air, nitrogen gas and oxygen requirements. Our air receiver tanks are manufactured to stringent CE standards and further certified to meet New Zealand seismic requirements.

270 to 1,500 litres, 11-bar, paint finish PneuTech air receivers are available now (ex-stock). All other sizes and finishes up to 20,000 litres are available to order. Contact us below with your air receiver requirements, or check out our complete range.

270 Ltr - 20,000 Ltr. Certified to all New Zealand regulations. Up to 1,500 litres, 11 bar pressure, available ex-stock in New Zealand. Up to 40 bar available to order.

270 Ltr - 20,000 Ltr. For long-lasting weather-proof storage. Galvanised air receivers are available to order, with a 2-3 month lead time. 11, 16, or 40 bar pressure.

270 Ltr - 20,000 Ltr. Suitable for sterile locations, stainless steel air receivers are available to order in 11, 16 or 40 bar pressure. 2-3 month lead time.

Industrial Air Systems supplies PneuTech air receivers to New Zealand sites that depend on reliable compressed air, nitrogen and oxygen, including:

In these industries, an air receiver helps to:

Because Industrial Air works across so many of these sectors, the team can recommend receiver sizes and configurations that match how your plant actually uses air rather than relying only on compressor nameplate figures. Whether you are planning a new installation or upgrading an existing system, we can help you choose an air receiver that fits your industry, site layout and compliance needs. For more detail on capacities and options, download the air receivers brochure on this page.

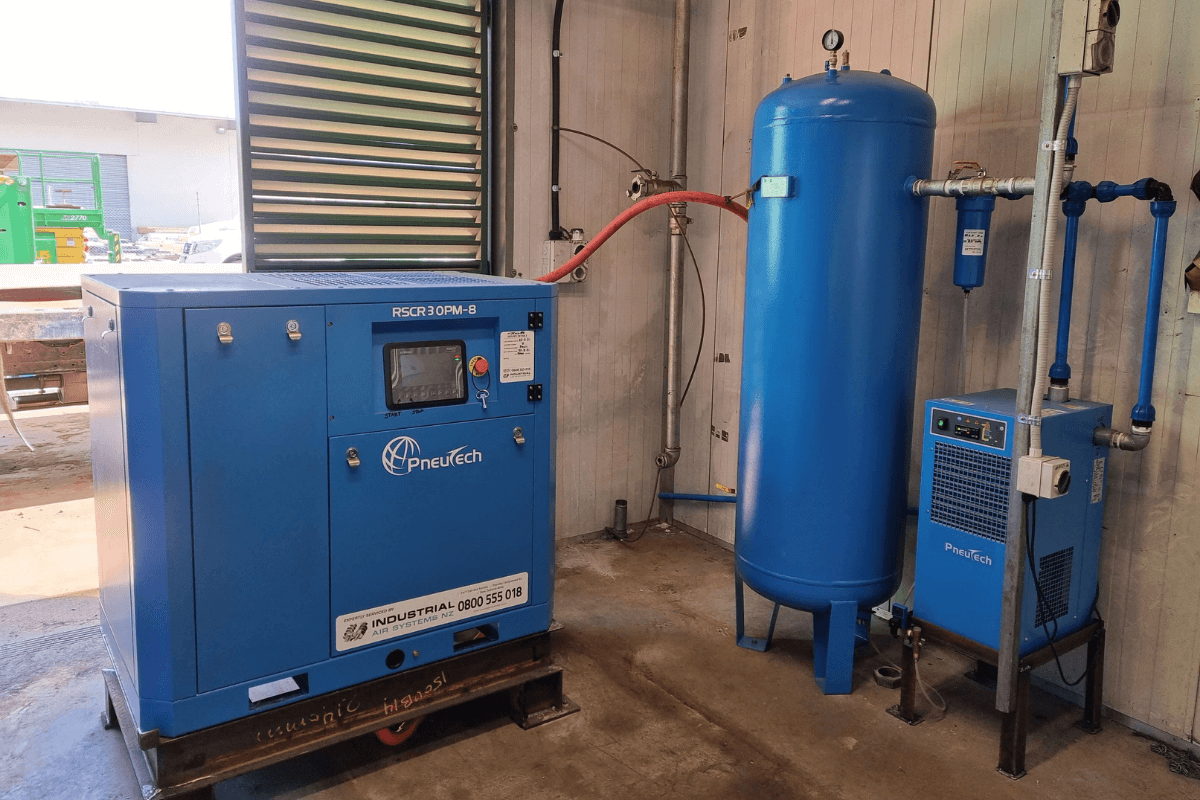

In an Industrial Air system, the air compressor is the machine that does the work of compressing ambient air, while the air receiver is a pressure vessel that stores that compressed air after it leaves the compressor. The receiver provides a reserve of air, helps smooth out peaks in demand and stabilises system pressure so your equipment can run consistently and efficiently.

To read more about the role of the receiver in the overall system, see the article What is an air receiver used for?

Industrial Air recommends sizing an air receiver by looking at both your compressor output and how your plant uses air. As a general guideline, they suggest allowing around 10 to 15 litres of tank volume for every CFM of compressor capacity. For example, a 100 CFM compressor typically needs about 1,000 to 1,500 litres of receiver capacity.

From there, you refine the size based on peak usage, how much your demand fluctuates, the pressure you need at the tools, the volume of air already stored in your pipework, and the type of compressor you are using. Systems with sharp peaks or reciprocating compressors often benefit from larger receivers, while some rotary screw compressors can operate with less storage. For a step by step walkthrough, refer to How to correctly size a compressed air receiver tank.

An air receiver is usually installed as part of a complete compressed air plant, so the exact installation will depend on your building layout, compressor type and piping design. Industrial Air emphasises that every plant installation is unique and should be engineered so the receiver is correctly positioned, securely mounted, piped into the system and fitted with drains, a pressure gauge and safety relief valve.

When you purchase a compressed air system from Industrial Air Systems, their in house projects team can plan and carry out the plant installation, including air receivers, to a professional standard. To learn more about this service, visit the Servicing and Support page.

Location depends on space and how your system operates. Industrial Air note that many smaller compressors are supplied already mounted on a receiver to save floor space, while larger compressors often use separate receivers. In some plants it is best to use several tanks, with a larger storage receiver close to the compressor and smaller receivers installed near points of use to stabilise pressure at critical equipment.

Receivers can be installed indoors or outside, but units located outdoors should be inspected regularly for signs of corrosion and maintained promptly to protect the vessel.

We highlight two key aspects of air receiver maintenance: draining condensate and staying compliant with inspection requirements. Without an air dryer, moisture can build up inside the tank, leading to internal corrosion, blocked piping and damage to downstream equipment. To avoid this, we recommend draining the receiver daily, ideally with an automatic condensate drain to remove moisture build up.

In New Zealand, air receivers must also follow inspection and certification requirements. We note that receivers typically need a thorough inspection at least every ten years to stay compliant and safe in operation, and we can arrange those inspections as part of our service offering. Alongside this, the receiver should always be fitted with correctly rated accessories such as a pressure gauge, safety relief valve and drain.

Compressed air system for a leading engineering company in Christchurch

Pegasus Engineering can have many projects underway at one time which means that their workshop and equipment needs to operate at peak efficiency. Compressed air plays a vital part in keeping important machinery running effectively.

View case study

The friendly Industrial Air Systems team are here to help! Contact us now with your compressed air request and we'll be back in touch by phone or email, as soon as possible.

Excellent service. Your guys have all been very, very good. You were willing to work around our production needs and come out in the middle of the night to get amongst the rats!

We’ve been staying with these guys because they have the right skills and experience.

Top-rate service. I would recommend your company. I hope we get Paul every time!

We had an issue with the compressor which these guys fixed. We’re very pleased with Industrial Air Systems. They reacted quickly, kept the unit running while a part was sourced and then fixed it quickly. When we’re looking at any upgrades Industrial Air Systems will be our first port of call.

You ticked all the boxes. Your guys were great. You come in, do the job and leave a pack of biscuits!

Paul has done a very nice job installing the pipework, it looks awesome. I’m glad that you recommended the aluminium pipe.

We have found Industrial Air Systems very good to deal with and very professional. Good service at a good price. I would not hesitate to recommend Industrial Air Systems to any company considering using them.

[Your tech] is a great guy to work with, he has great knowledge with all the gear and is always there when we need him. All the guys here at VIP love working with him.

We have had a good experience working with Industrial Air Systems – they are easy to do business with and we have no hesitation recommending them to companies wanting an efficient and economical supply for compressed air.

We have found their service team very responsive and excellent to work with, and from our good experience we would recommend Industrial Air Systems to any company requiring compressed air in the future.

We are very happy with the airlines and the setup. The whole process was easy and we received great communication from you and the team. Your contractor was also great to deal with and did a very tidy job of the install.

Industrial Air Systems NZ © 2026