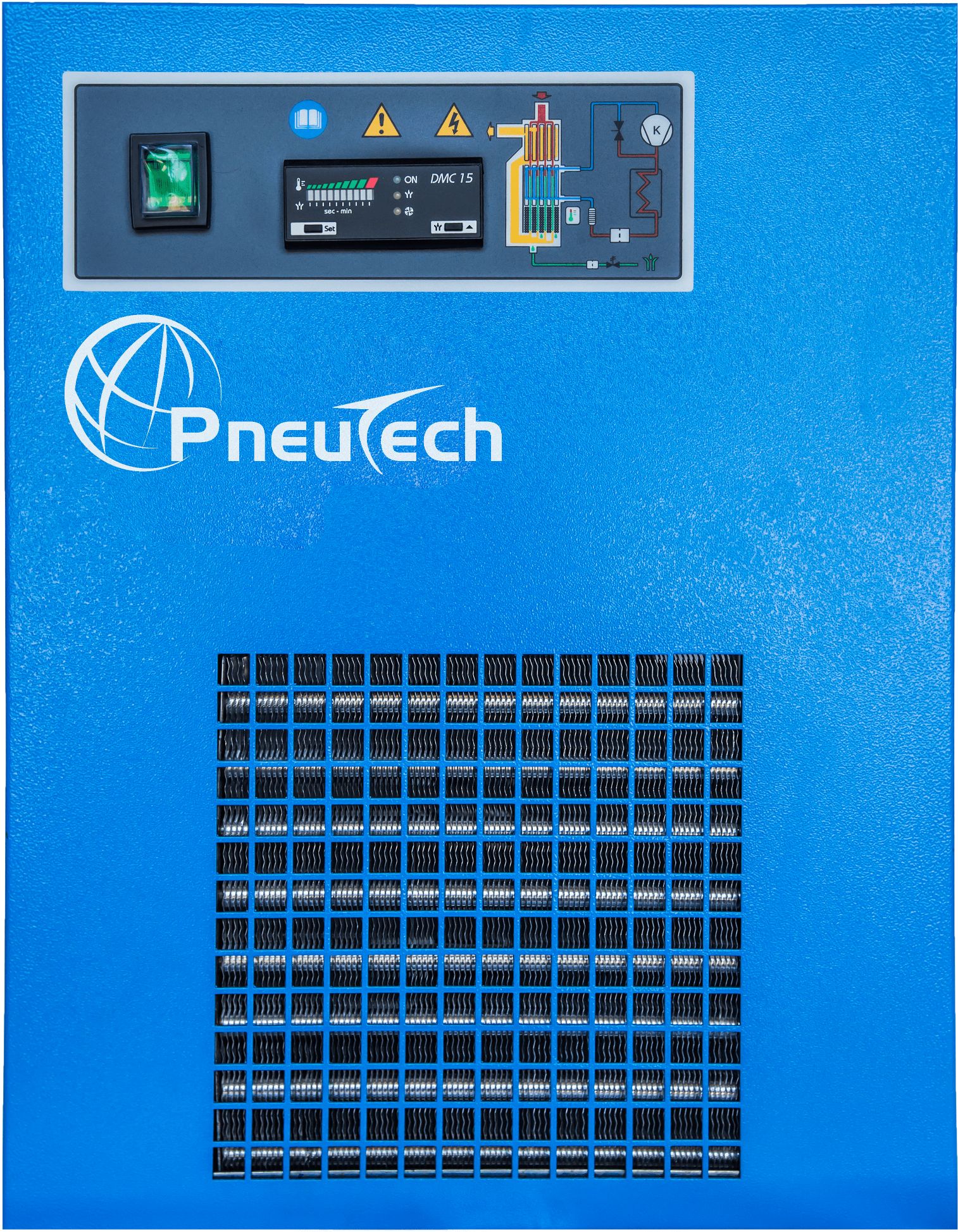

Refrigerated dryers

With an ambient temperature capacity of 5 to 50°C, the PneuTech PDR refrigerated dryers can perform in extreme temperatures and high humidity to produce 99% moisture-free compressed air every time.

With a generously spaced cabinet and oversized components such as the heat exchanger, cooling fan and industrial compressor, the PDR dryer is designed for optimum performance whilst providing low-cost operation.

Special features such as the stainless steel heat exchanger (models up to 141cm), low energy requirement and low maintenance costs, make the PneuTech refrigerated dryer the number one choice in every industrial compressed air situation, where long term and reliably dry air is critical.

For more information on the range of dryers available, download our free brochure.

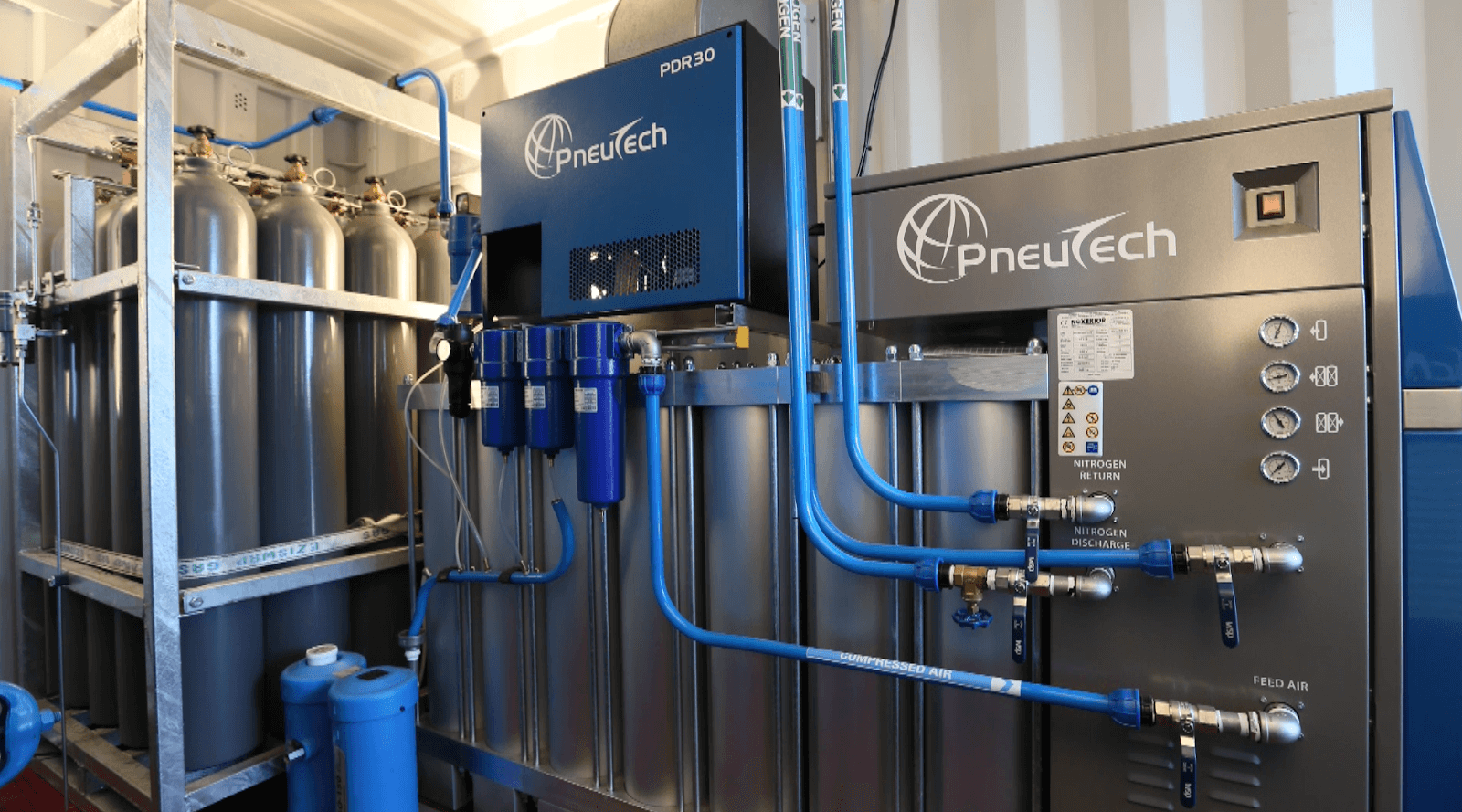

Desiccant Dryers

PneuTech adsorption dryers totally clean and dry compressed air down to -40°C pressure dew-point as standard.

For critical applications, adsorption dryers can be specified to provide a pressure dew-point of -70°C. A pressure dew-point of -26°C or better will not only prevent corrosion but will also inhibit the growth of micro-organisms within the compressed air system – critical to some applications.

While adsorption dryers guarantee a very safe and dry compressed air supply, the process does account for some pressure drop in the compressed air supply, which in turn requires greater air pressure input and thus higher energy costs.

The PneuTech adsorption dryers incorporate specially designed and matched components working in synergy to produce optimum air flow rates with minimal pressure drop, averaging only 0.35bar including pre and after filters.

This minimal pressure drop constitutes 50% less energy consumption over conventional adsorption dryers, leading to huge electrical savings every year.

For more information on the range of dryers available, download our free brochure.

How do refrigerated dryers work?

A refrigerated dryer processes hot, moisture-laden air from the compressor, down to the dew-point temperature (3°C) in three stages - firstly through a heat exchanger, then through a refrigerant/air exchanger, which brings it down to dew-point, at which point the oil and water vapour condense into a droplet form and are drained off. The cold air then re-enters the heat exchanger and is reheated to normal working temperature.

How do desiccant dryers work?

PneuTech cold refrigerated desiccant dryers operate on the PSA (pressure swing adsorption) principle. Two drying towers filled with a powerful hygroscopic drying agent operate in conjunction to eliminate water particles from the compressed air supply down to a pre-set dew-point level. While one tower is drying the compressed air, the other tower is regenerating the drying agent, allowing for a continual, reliable supply of moisture-free air, through this cycling process.

What is required for servicing a dryer?

Refrigerated dryers typically require very little servicing outside cleaning the condenser (recommended yearly) and checking drains are working correctly. Filtration attached to the refrigerated dryer as part of the compressed air set-up should have the elements changed a minimum of 12 monthly – more frequent replacement may be required for high usage. Desiccant dryers also incorporate pre and after-filters, and these should be changed at minimum in 12-month intervals, or more frequently for high-running hours. The desiccant inside the dryer should be serviced at 24-month intervals or earlier if indicated by the inbuilt sensors.

Learn more about the different dryers available and find product specifications in the free brochure here.

.jpg)