This year we’ve had the chance to work on a range of different compressed air projects across New Zealand ranging from small to large, and unique to truly spectacular. So whether you’re keen to take a look at what we’ve worked on this year, or perhaps you’re looking for ideas for a new compressed air set up for your workshop or factory, we’ve got it covered!

We asked the team here at Industrial Air Systems to share their favourite projects of the year. From air receivers for a winery in Blenheim, to an enclosed compressor system for a chocolate cafe, there are a number of really interesting projects that really stood out to the team!

Learn about our favourite compressed air projects of 2020 and see what makes them so special below.

Nick Richards

Nick Richards

Director

Favourite project:

Compressed air system for Allegion in Auckland

Allegion is a large manufacturer and exporter of door hardware and security systems. This was my favourite project for the year as they were building a completely new manufacturing facility featuring multiple workstations and a specialist plant – all requiring clean, dry compressed air, but without any knowledge of the capacity requirement needed.

We also supplied a separate blower system and reticulation to supply low pressure air for agitating a number of metal plating baths, again without capacity requirements.

We scoped the high and low pressure air capacity requirements based on experience, and worked with Allegion engineers to design a reticulation piping system with over 40 droppers to convey the air throughout the factory and installed the complete set up all within the given timeframe.

The challenge was to scope their varying high pressure and low pressure air requirements, and supply the most efficient system to suit both requirements.

After in-depth calculations, we proved that separate low and high pressure systems provided the highest performance, and most cost-effective solution.

Video footage of the Allegion aluminium piping system.

Plant included:

Compressed Air System

- RSCR20PM 15kw VSD compressor

- PDR Refrigerated Dryer

- 2-stage filtration

- 300m of 40mm aluminium air ring main with 43 droppers with double couplers.

Blower System

- FPZ 5.5kw 3” Side Channel Blower

- 63mm Arterial Main, with multiple take off points to feed the baths

Compressed air system for Allegion.

Jacqui Richards

Jacqui Richards

Director

Favourite project:

Air receivers for a winery in Blenheim

My favourite project would have to be the winery project in Blenheim, where we supplied 11 large air receivers for a combination of compressed air, and nitrogen requirements.

We supplied 11 air receivers from 1,000 Ltr to 10,000 Ltr for both compressed air, and nitrogen. The customer had a very tight time-frame from order confirmation to delivery, and although this got delayed due to global shipping issues, our supplier was able to manufacture the order and have it ready for dispatch within just over 3 weeks. Hilton Haulage also assisted us with delivery and off-loading in New Zealand, and the receivers are being installed this week. It really is an impressive amount of air receivers for one site.

Air receivers on their way to a winery in Blenheim.

Air receivers on their way to a winery in Blenheim.

Jeremy Richards

Jeremy Richards

Regional Sales Manager

Favourite project:

Nitrogen generation plant for Heartland Chips in Timaru

My favourite project this year has to be the Nitrogen generation plant we supplied for Heartland Chips in Timaru.

We not only supplied but also installed an onsite N2 generation plant, for constant feed to their chip bagging machine. We also worked in with requests and installed in an area which was seen as “dead” space in their factory.

Products used:

- PneuTech “power saving” VSD Vixen screw compressor

- PneuTech nitrogen generator

- PneuTech compressed air and nitrogen storage receivers

- PneuTech refrigerated dryer and 4 stage filtration

- PneuTech Alu Air piping

This new nitrogen generation system runs for up to 19hrs per day supplying N2 for two shifts. The machine has already performed faultlessly for over 2500hrs since it was installed and is in a regular service program.

Nitrogen generation plant for Heartland Chips.

Nitrogen generation plant for Heartland Chips.

Stacey Smith

Stacey Smith

Procurement Team Leader

Favourite project:

Enclosed compressed air system for Miann Chocolate in Auckland

A compressor setup in a cafe? No, we’re not joking! When this customer initially came to us with their ideas for an enclosed air compressor system that would be housed at a cafe, it had us scratching our heads wondering if they were serious!

We managed to find a suitable solution for this customer’s needs – the EncloseAir. This compressed air system features a 10HP Vixen series permanent magnet, rotary screw compressor, dryer and filtration, all installed in a custom zincalume enclosure.

Another cool thing about Miann is that they installed glasshouses for patrons to keep separate during COVID restrictions. It’s proved popular and with such a quiet compressor running nearby, we helped Miann ensure that there are no noisy interruptions to their client’s in-store dining experience.

The EncloseAir compressed air system at Miann Chocolate.

India Richards

India Richards

Administration & Service Support

Favourite project:

Containerised nitrogen generation plant for Aabaas Industries in Christchurch

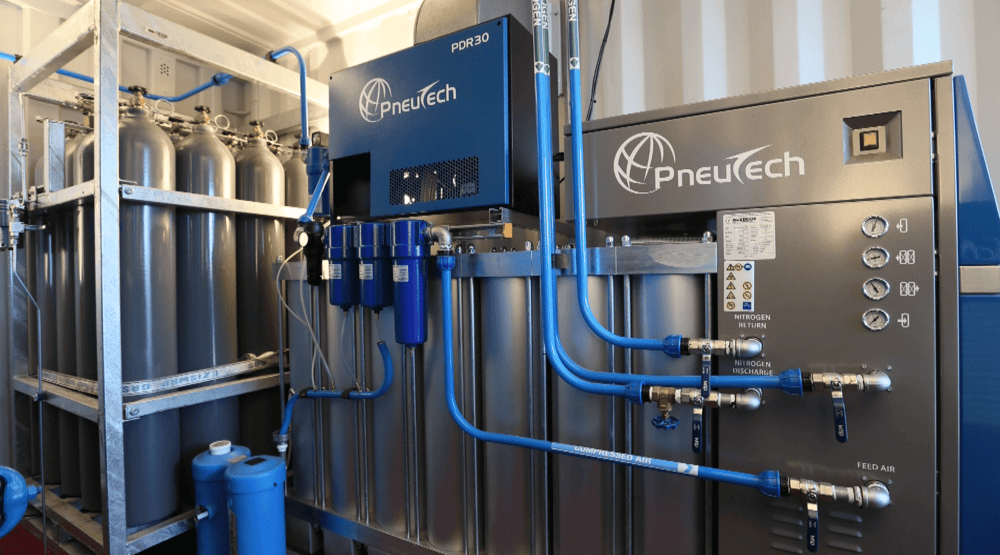

This was my favourite project of the year because it was assembled onsite at our Timaru facility, and we were able to get an up-close look at the finished product which we don’t get to see very often. The workman-ship from our technician was impressive, with lots of attention paid to the pipework detail and overall layout to make sure everything was easily accessible for ongoing servicing.

The set-up included a 30HP compressor, nitrogen generator, booster compressor, air and nitrogen receivers, high-pressure nitrogen storage, low and high pressure filtration, condensate separators and lots of pipework, valves and drains. The overall package was designed to deliver over 29m3 per hour at 99.99% purity.

Containerised nitrogen generation plant for Aabaas industries.

Learn more about the benefits of on-site nitrogen generation in our video >

Daniel Strachan

Daniel Strachan

Service Team Leader

Favourite project:

Enclosed compressed air system for Tourism Holdings in Auckland

My favourite project this year was for Tourism Holdings in Auckland. Sadly this customer was hit with a major fire to their premises on the 3rd of September, which meant a whole new set-up was required. They had a very tight time frame, and needed a completely new piping fit-out and compressed air installation in a temporary building, in a hurry!

One of the customer’s requirements was that everything was easily relocatable for when they moved into their own premises, so an EncloseAir compressor was chosen. This is a weather-proof, ventilated and ducted, noise-insulated package, with 40HP permanent magnet compressor, refrigerated dryer, filtration, and air receiver. It was delivered to site fully commissioned and ready to plug into their power supply, and is simply disconnected, and uplifted to the new site when ready.

The EncloseAir compressed air system supplied for Tourism Holdings.

The project also included 350m of 40mm aluminium air piping with 20mm and 25mm droppers and hose reels. The whole Alu Air system is completely reusable at another site. We were able to get the project completed in a timely manner, and the customer is very happy with the end result.

350m of aluminium air piping was also supplied for this project.

There you have it – our favourite compressed air projects for 2020! If you have any questions about the projects mentioned and the products used for these systems, or perhaps you’d like to know more about the EncloseAir, feel free to get in touch with the team here.

.jpg)